REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1

BUTTERFLY VALVE

CONCENTRIC WATER TYPE

Lever Operated Type Manual Actuation

- 1Description

LYE Wafer Type Butterfly Valves, resilient centerline with full internal rubber lining vulcanized to the body with quarter turn operating for system isolation. Rubber covered internal body makes no risk of corrosion, and as well as tight sealing of disc closure with no deformation of liner. It is designed to fit the majority of flange standards, to be connected with flange at the pipe end through a set of bolts/nuts. LYE Wafer type butterfly valve is light in weight and its compact design with great installation advantages with easy disassembly, cost efficient and small occupancy of space . • Quarter-Turn Isolating Valves With Full Rubber Covered Body

• For System Operation & Maintenance• Working Pressure : 10/16 Bar • Disc Strength : 15/24 Bar • Seat Test Pressure : 11/17.6 Bar • Temperature Range : 0°C – 80°C • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : BS EN 593 • Top Flange : ISO 5211 • For Connecting End : BS EN 1092 PN10/16, ASME B16.1 CL125, ASME B16.5 CL150, JIS 10K, BS Table E/D . Features • Range of Valve Sizes : DN40 to DN600 • Standard Valve Actuator : >=DN300 Lever (Worm Gear Operated by Request) ,

: >=DN350 Only Worm Gear Operated With Handwheel• Universal Flange Connection : • Standard ISO Top-Flanged for actuator • Compact Design Requires Considerably Less Space & Light In

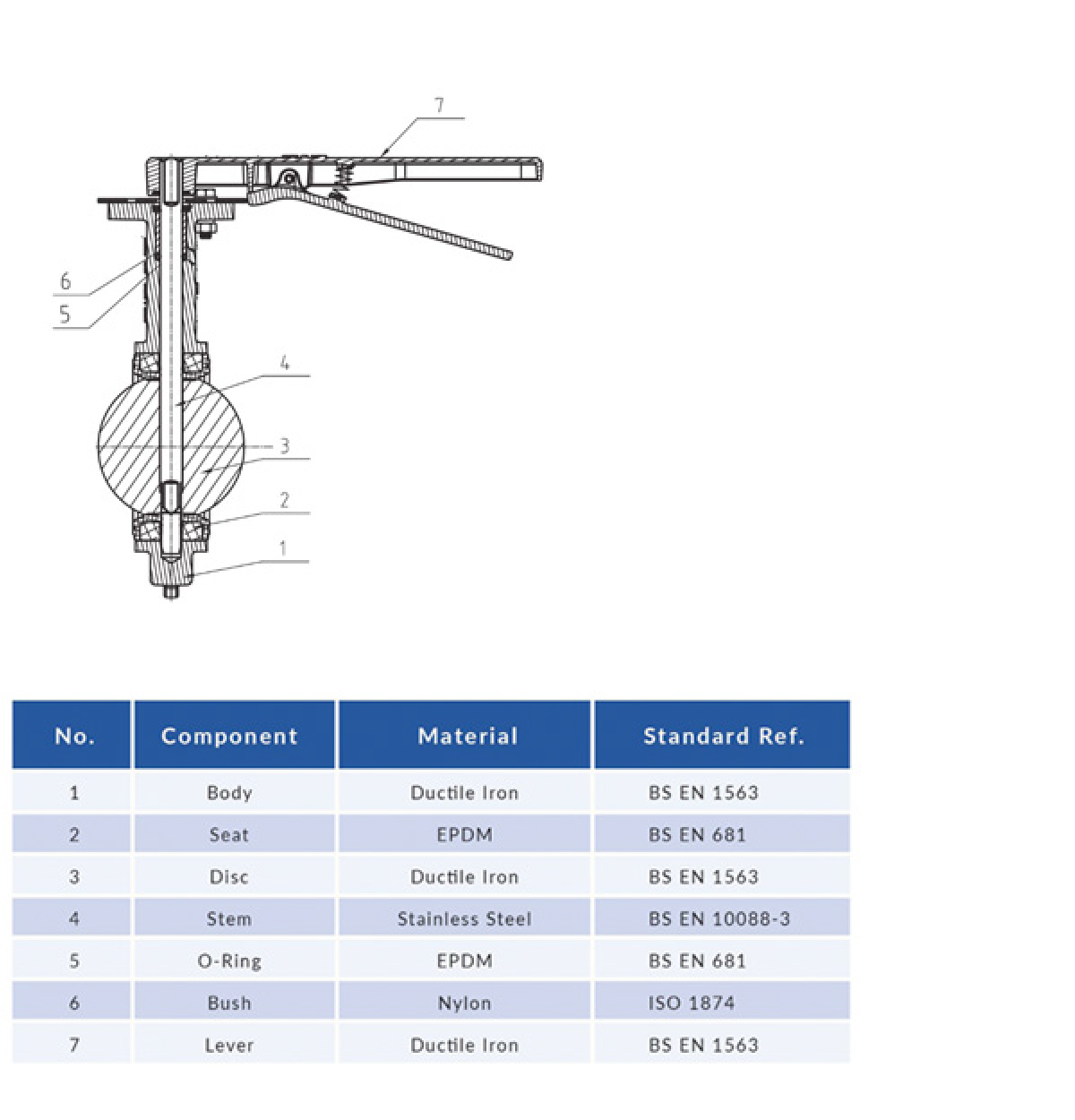

• Weight• Quick Operation Requires Less Time To Open Or Close - 2Parts List & Materials

- 3Specifications & Parameters Chart

BUTTERFLY VALVE

CONCENTRIC WATER TYPE

Lever Operated Type Manual Actuation

- 1Description

LYE Wafer Type Butterfly Valves, resilient centerline with full internal rubber lining vulcanized to the body with quarter turn operating for system isolation. Rubber covered internal body makes no risk of corrosion, and as well as tight sealing of disc closure with no deformation of liner. It is designed to fit the majority of flange standards, to be connected with flange at the pipe end through a set of bolts/nuts. LYE Wafer type butterfly valve is light in weight and its compact design with great installation advantages with easy disassembly, cost efficient and small occupancy of space . • Quarter-Turn Isolating Valves With Full Rubber Covered Body

• For System Operation & Maintenance• Working Pressure : 10/16 Bar • Disc Strength : 15/24 Bar • Seat Test Pressure : 11/17.6 Bar • Temperature Range : 0°C – 80°C • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : BS EN 593 • Top Flange : ISO 5211 • For Connecting End : BS EN 1092 PN10/16, ASME B16.1 CL125, ASME B16.5 CL150, JIS 10K, BS Table E/D . Features • Range of Valve Sizes : DN40 to DN600 • Standard Valve Actuator : >=DN300 Lever (Worm Gear Operated by Request) ,

: >=DN350 Only Worm Gear Operated With Handwheel• Universal Flange Connection : • Standard ISO Top-Flanged for actuator • Compact Design Requires Considerably Less Space & Light In

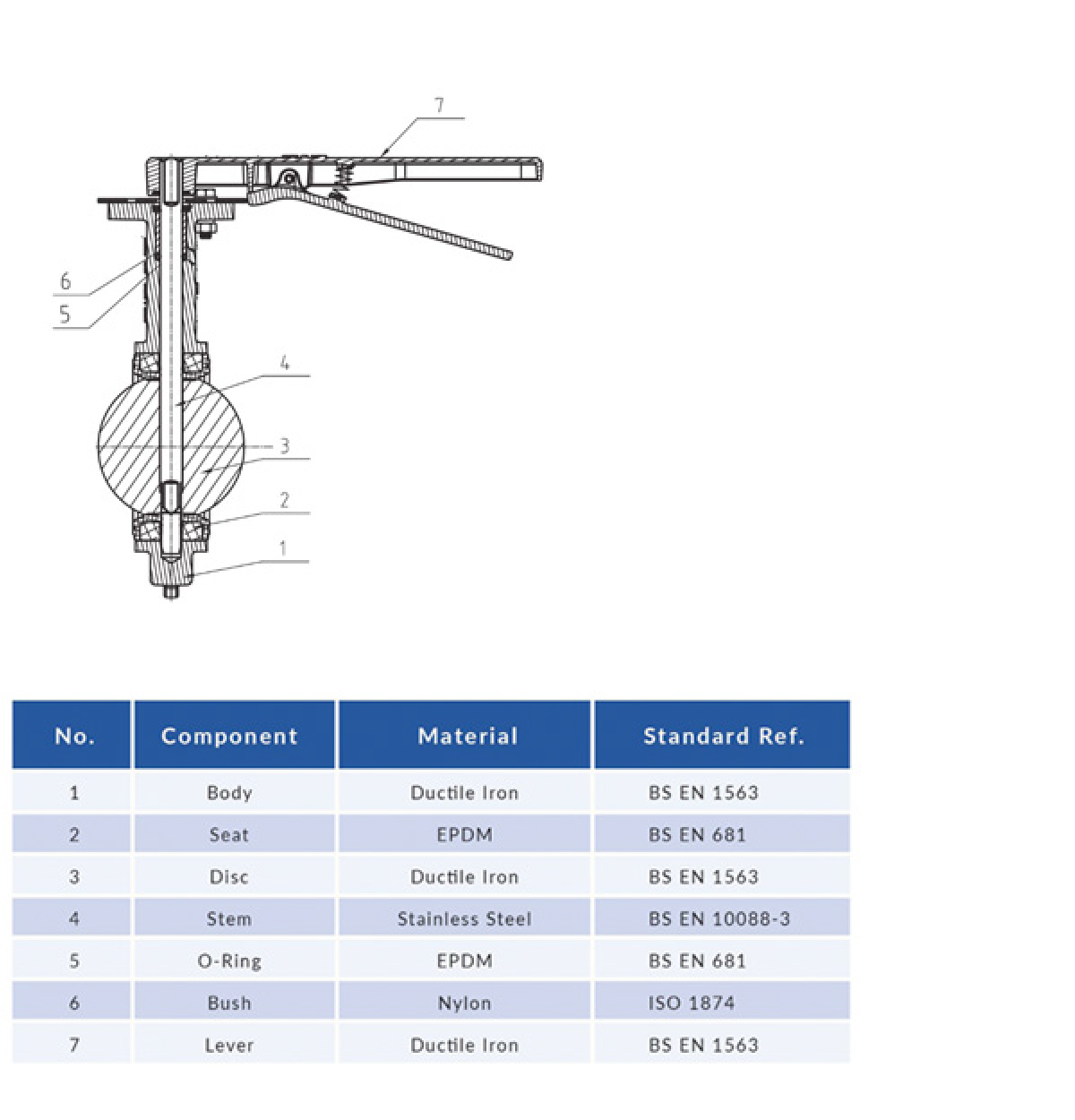

• Weight• Quick Operation Requires Less Time To Open Or Close - 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1