REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1

SLUICE VALVES

METAL SEATED

Double Flanged PN10/16, Type B Cap Top (Option : Handwheel Operated)

Model No. : LYE 555D.I.

- 1Description

LYE Non-Rising Stem Metal Seated Gate Valves or commonly known as Sluice Valves is designed to comply heavy duty BS 5163 Type B Standard for water & waste water application, and as well as BS EN 1171 / BS EN 1074 Standard for industrial application available in sizes up to 1400mm. Multi-turns isolating valve with metal-seated wedge gate disc for watertight bearing by gunmetal seat sealing and a stainless steel stem. Valve body is coated Internally and externally with polymeric coating-fusion bonded epoxy coating. For large diameter gate valves can be supplied both with and wihtout by-pass valve options, and by-pass valve is always recommended as safety practices for pressure equalizing and water hammer prevention in the system. . • Multi-Turn Isolating Valves with metal-seated wedge gate disc

• for system operation and maintenance• Design for accommodating various type of actuators, from manual

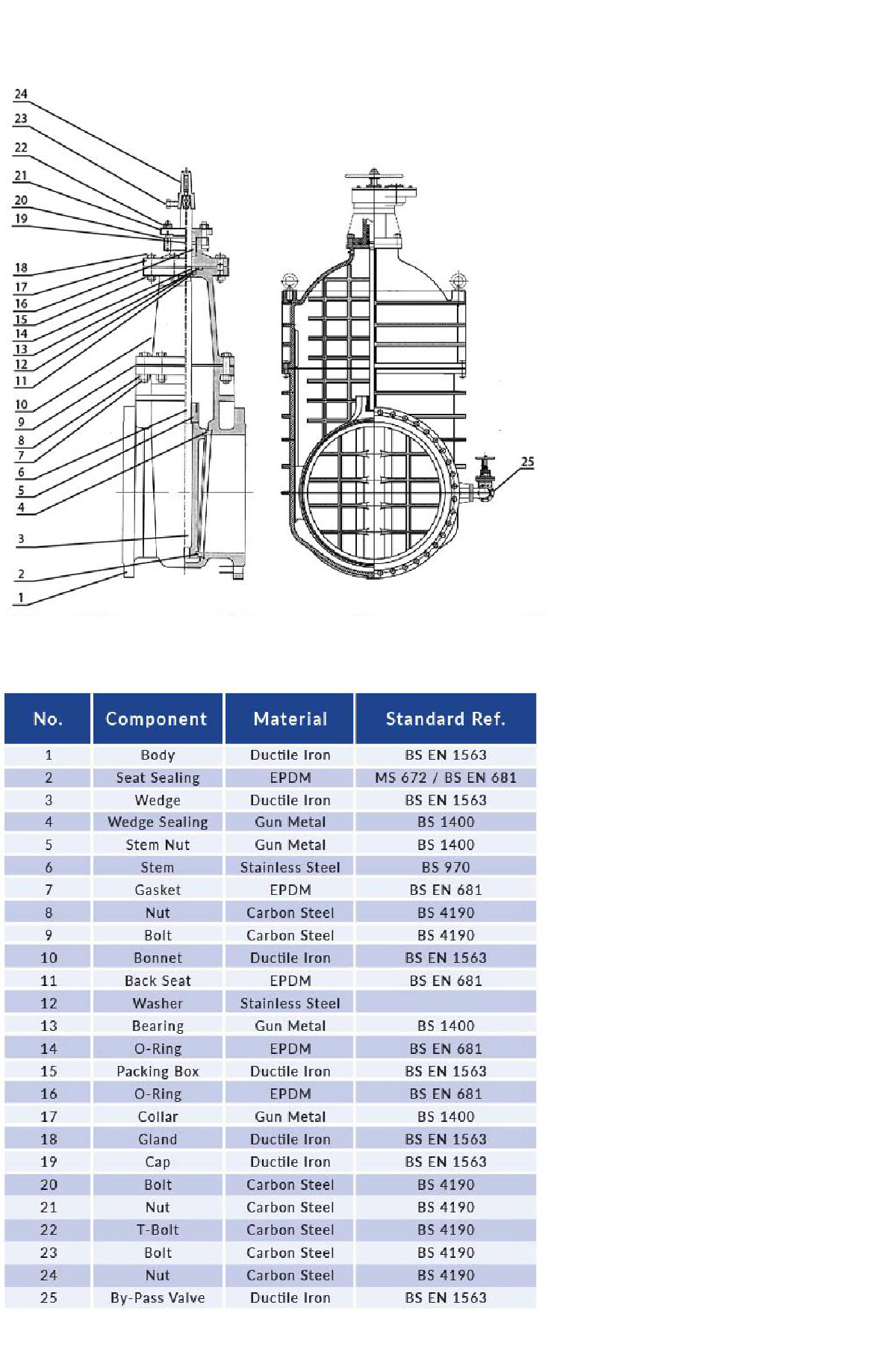

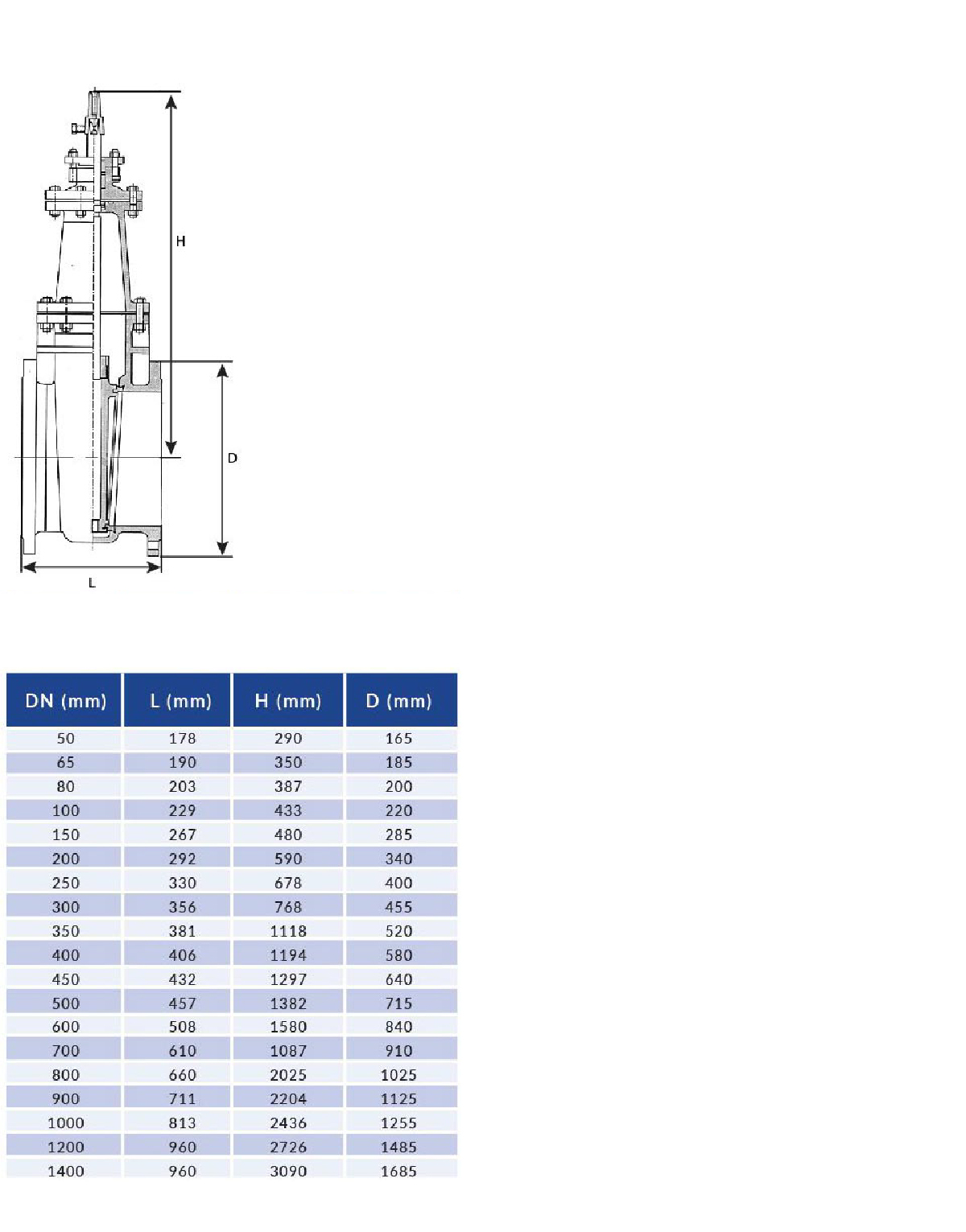

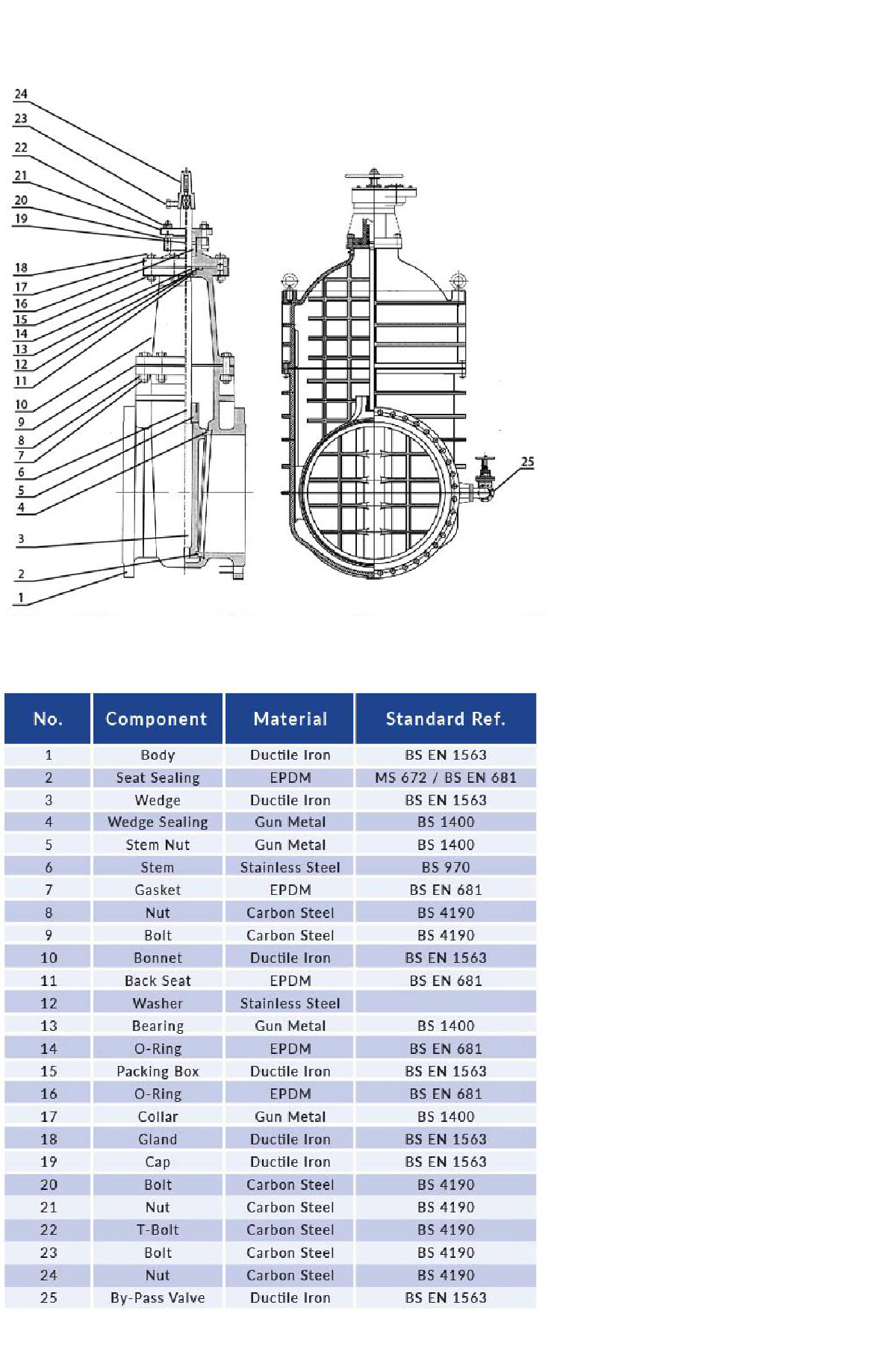

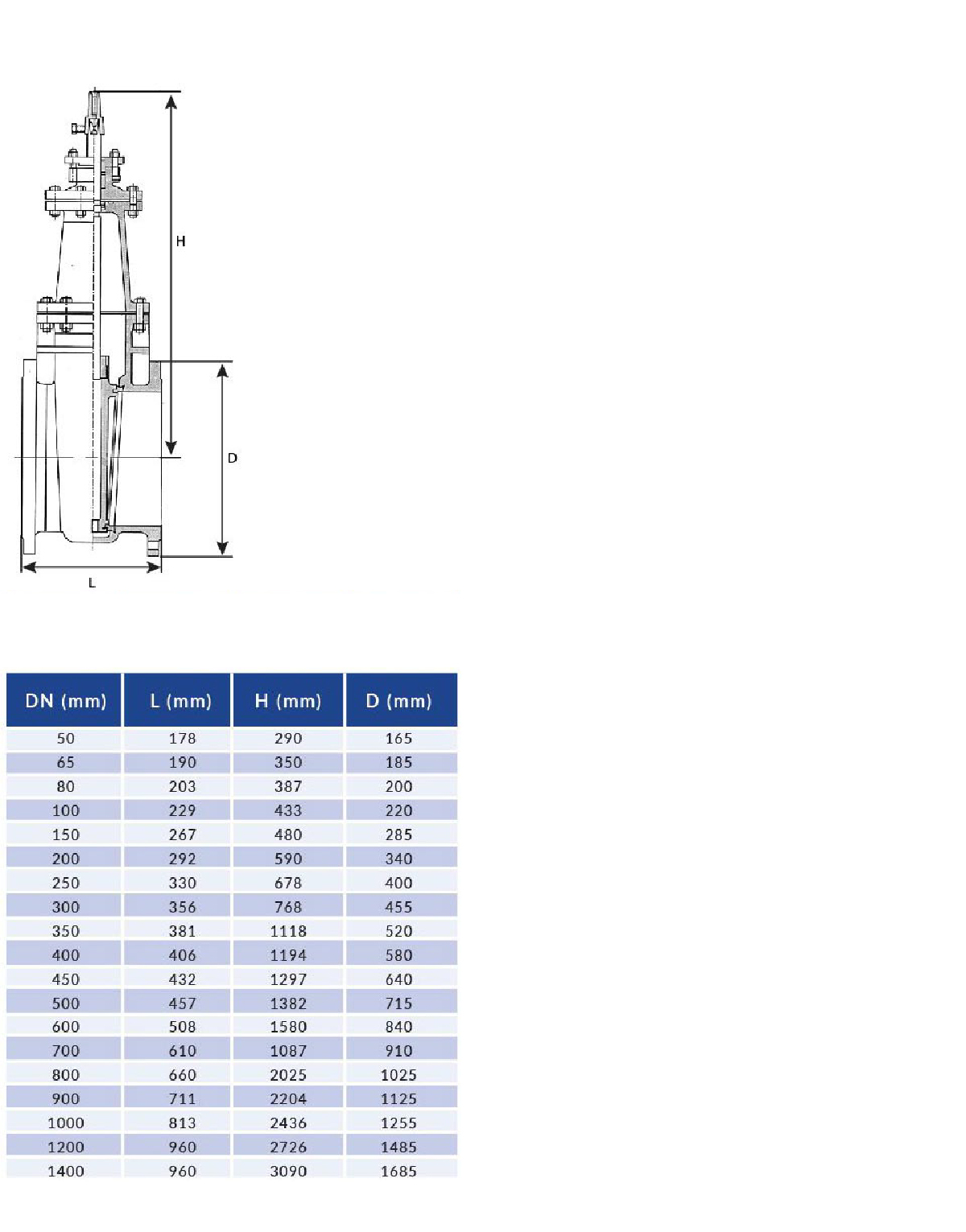

• actuation, to electric & pnuematic actomatic actuators.• Working Pressure : 16 bar • Shell Pressure : 24 bar • Seat Pressure : 17.6 bar • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : BS 5163 & BS EN 1171 • Test : BS EN 1074 • Flange : BS EN 1092-2 • Face to Face : EN 558-1, Series 3 . Features • Range of Valve Sizes : DN50 to DN1400 • Standard Cap Top & Option With Handwheel • Option With Complete Handwheel With Spur Gear (>=DN350) • Option With Complete By-pass Valve (DN450 – DN1400) - 2Parts List & Materials

- 3Specifications & Parameters Chart

SLUICE VALVES

METAL SEATED

Double Flanged PN10/16, Type B Cap Top (Option : Handwheel Operated)

Model No. : LYE 555D.I.

- 1Description

LYE Non-Rising Stem Metal Seated Gate Valves or commonly known as Sluice Valves is designed to comply heavy duty BS 5163 Type B Standard for water & waste water application, and as well as BS EN 1171 / BS EN 1074 Standard for industrial application available in sizes up to 1400mm. Multi-turns isolating valve with metal-seated wedge gate disc for watertight bearing by gunmetal seat sealing and a stainless steel stem. Valve body is coated Internally and externally with polymeric coating-fusion bonded epoxy coating. For large diameter gate valves can be supplied both with and wihtout by-pass valve options, and by-pass valve is always recommended as safety practices for pressure equalizing and water hammer prevention in the system. . • Multi-Turn Isolating Valves with metal-seated wedge gate disc

• for system operation and maintenance• Design for accommodating various type of actuators, from manual

• actuation, to electric & pnuematic actomatic actuators.• Working Pressure : 16 bar • Shell Pressure : 24 bar • Seat Pressure : 17.6 bar • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : BS 5163 & BS EN 1171 • Test : BS EN 1074 • Flange : BS EN 1092-2 • Face to Face : EN 558-1, Series 3 . Features • Range of Valve Sizes : DN50 to DN1400 • Standard Cap Top & Option With Handwheel • Option With Complete Handwheel With Spur Gear ( >=DN350) • Option With Complete By-pass Valve (DN450 – DN1400) - 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1