REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1

SLUICE VALVES

RESILIENT SEATED

Double Flanged PN10/16, Type B Cap Top (Option : Handwheel Operated)

Model No. : LYE 555D.I.

- 1Description

LYE Non-Rising Stem Resilient Seated Gate Valves or commonly known as Sluice Valves is designed to comply heavy duty BS 5163 Type B Standard for water & waste water applications

Advantages of LYE Resilient- Seated Sluice Valves- Straight through bore:

(a) Full Flow – The clear bore in the open position ensures optimum flow

(a) characteristics through the valve thereby reducing head loss

(b) Full Close – No accumulation of debris under the wedge enabling the valve

(b) to be fully closed - Lower operating torque

- Dust seal prevent ingress of foreign object

- Rubber covered gate

(a) Drop tight closure

(b) Would not be easily damaged by minor foreign object

(c) Gate chatter eliminated - Internal & external body is coated with polymeric coating-fusion bonded epoxy coating for excellent resistance to corrosion, abrasion, wear and tear

- Allow inspection and stem seal renewal under full operating pressure when gate is in open position

- Bolts sealed with wax to prevent corrosion

. • Multi-Turn Isolating Valves with drop-tight sealing for system

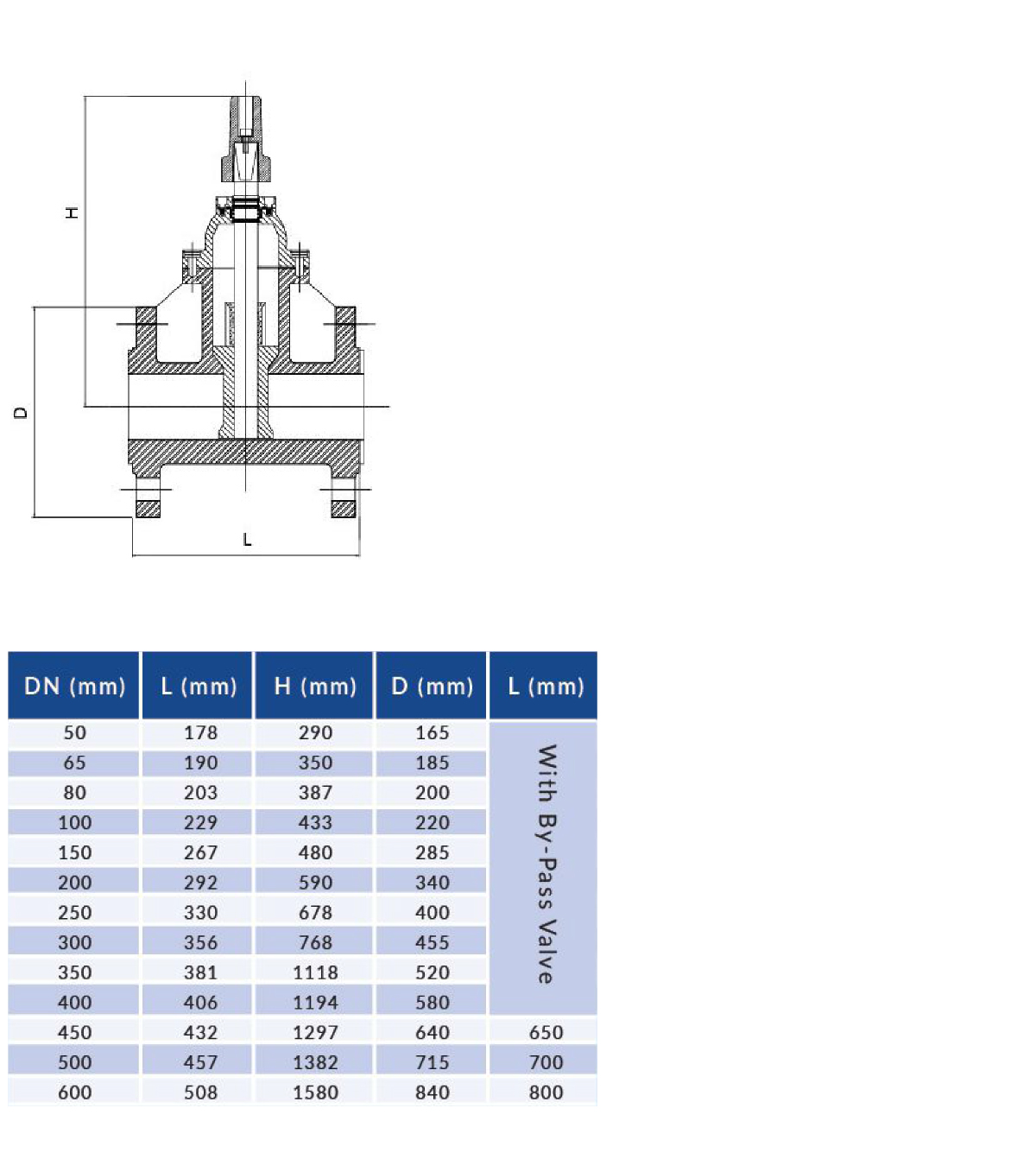

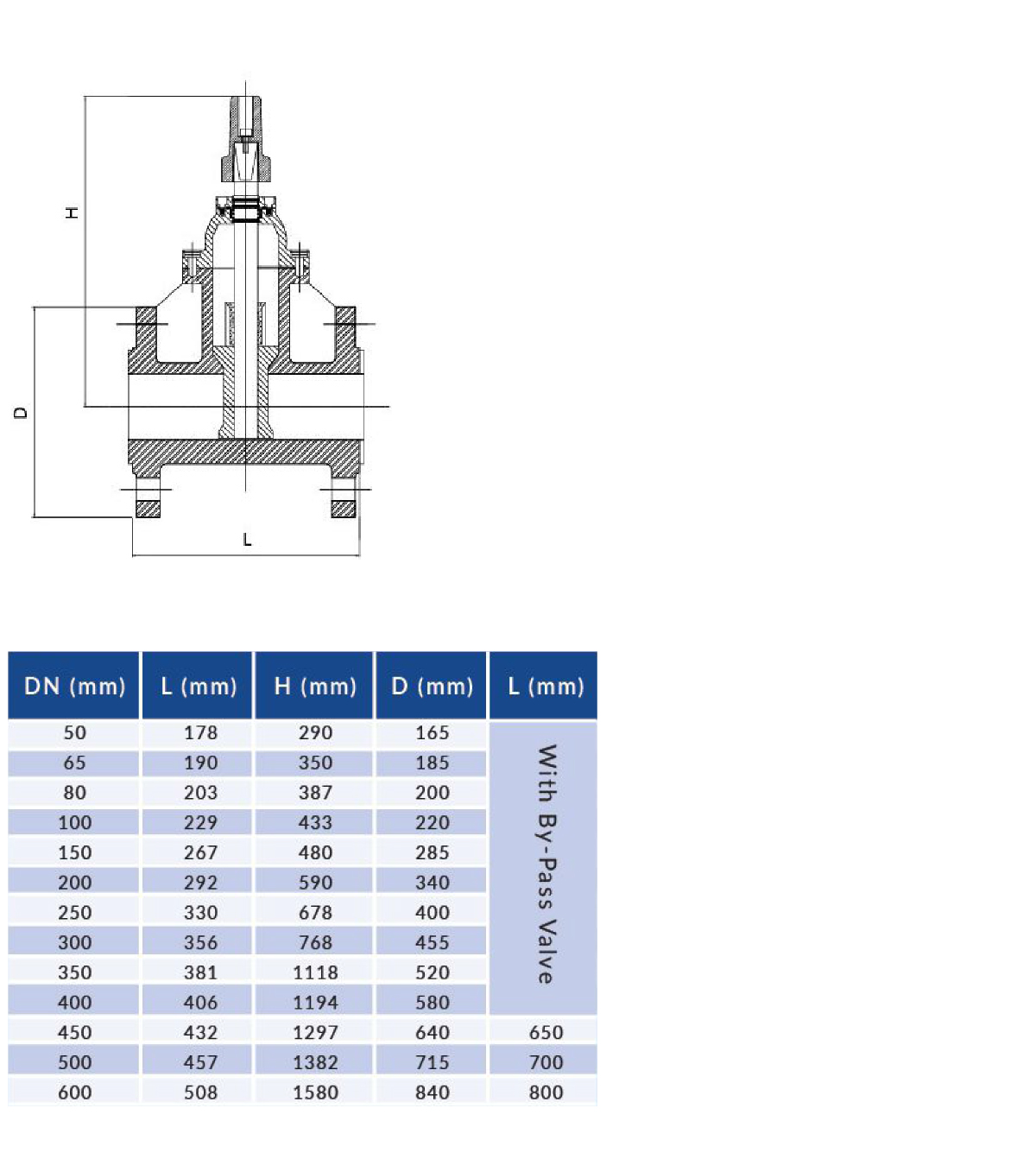

• operation and maintenance• Working Pressure : 10/16 bar • Shell Pressure : 15/24 bar • Seat Pressure : 11/17.6 bar • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : BS 5163 • Test : BS EN 1074-1 & 2 • Flange : BS EN 1092-2 • Face to Face : EN 558-1, Series 3 . Features • Range of Valve Sizes : DN50 to DN600 • Standard Cap Top & Option With Handwheel • Option With Complete By-pass Valve (DN450 – DN600) - Straight through bore:

- 2Parts List & Materials

- 3Specifications & Parameters Chart

SLUICE VALVES

RESILIENT SEATED

Double Flanged PN10/16, Type B Cap Top (Option : Handwheel Operated)

Model No. : LYE 555D.I.

- 1Description

LYE Non-Rising Stem Resilient Seated Gate Valves or commonly known as Sluice Valves is designed to comply heavy duty BS 5163 Type B Standard for water & waste water applications

Advantages of LYE Resilient- Seated Sluice Valves- Straight through bore:

(a) Full Flow – The clear bore in the open position ensures optimum flow

(a) characteristics through the valve thereby reducing head loss

(b) Full Close – No accumulation of debris under the wedge enabling the valve

(b) to be fully closed - Lower operating torque

- Dust seal prevent ingress of foreign object

- Rubber covered gate

(a) Drop tight closure

(b) Would not be easily damaged by minor foreign object

(c) Gate chatter eliminated - Internal & external body is coated with polymeric coating-fusion bonded epoxy coating for excellent resistance to corrosion, abrasion, wear and tear

- Allow inspection and stem seal renewal under full operating pressure when gate is in open position

- Bolts sealed with wax to prevent corrosion

. • Multi-Turn Isolating Valves with drop-tight sealing for system

• operation and maintenance• Working Pressure : 10/16 bar • Shell Pressure : 15/24 bar • Seat Pressure : 11/17.6 bar • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : BS 5163 • Test : BS EN 1074-1 & 2 • Flange : BS EN 1092-2 • Face to Face : EN 558-1, Series 3 . Features • Range of Valve Sizes : DN50 to DN600 • Standard Cap Top & Option With Handwheel • Option With Complete By-pass Valve (DN450 – DN600) - Straight through bore:

- 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1