REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

STRAINERS

Y-STRAINER

For Pipeline System, Equipments & Facility Protection

Model No, : LYE881

- 1Description

LYE Y-Strainer is designed for screen out solid materials and debris, it is commonly installed at upstream of metering system, inlet of control valves, or outlet of the pump for the protection of the important equipments in the pipeline system & facility from flow clogging, keeping the pipeline system in safe, clean and optimizing works efficiency. Advanced new design of perforated stainless steel screen for minimum cleaning, and suitable for both horizontal or vertical installation with screen position pointing downward, and for flow vertically downwards in vertical pipelines.

f

.

• Design for increasing the life span and reducing the maintenance cost of water meters & industry systems services

• For improving the reticulation for bulk meter system from Any Potential Damage Caused by Solid Materials & Debris

• Suitable for water & oil.

• Maximum temperature: < 100°C

• Working Pressure: PN16

• Shell Pressure: PN24

• Coating: Fusion Bonded Epoxy

• Sealing: EPDM.Standards

• Flange: EN 1092-2.Features

• Range of Strainer Sizes: DN50 to DN350

• Advanced new design of perforated stainless steel screen for minimum cleaning.

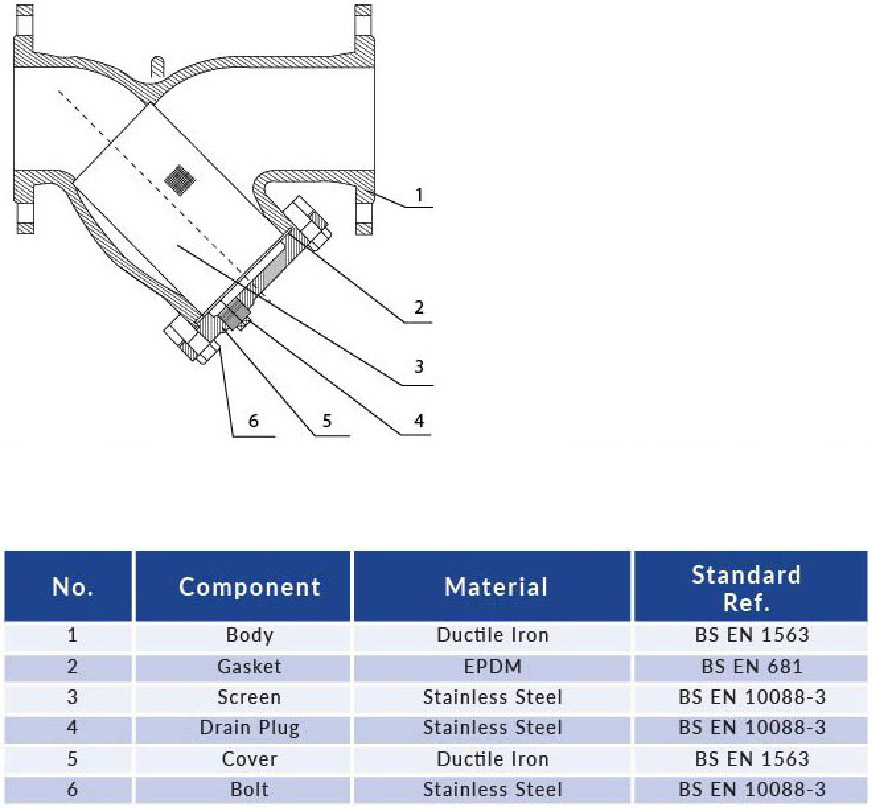

• Any dirt or debris accumulated can be flushed out through the drain plug - 2Parts List & Materials

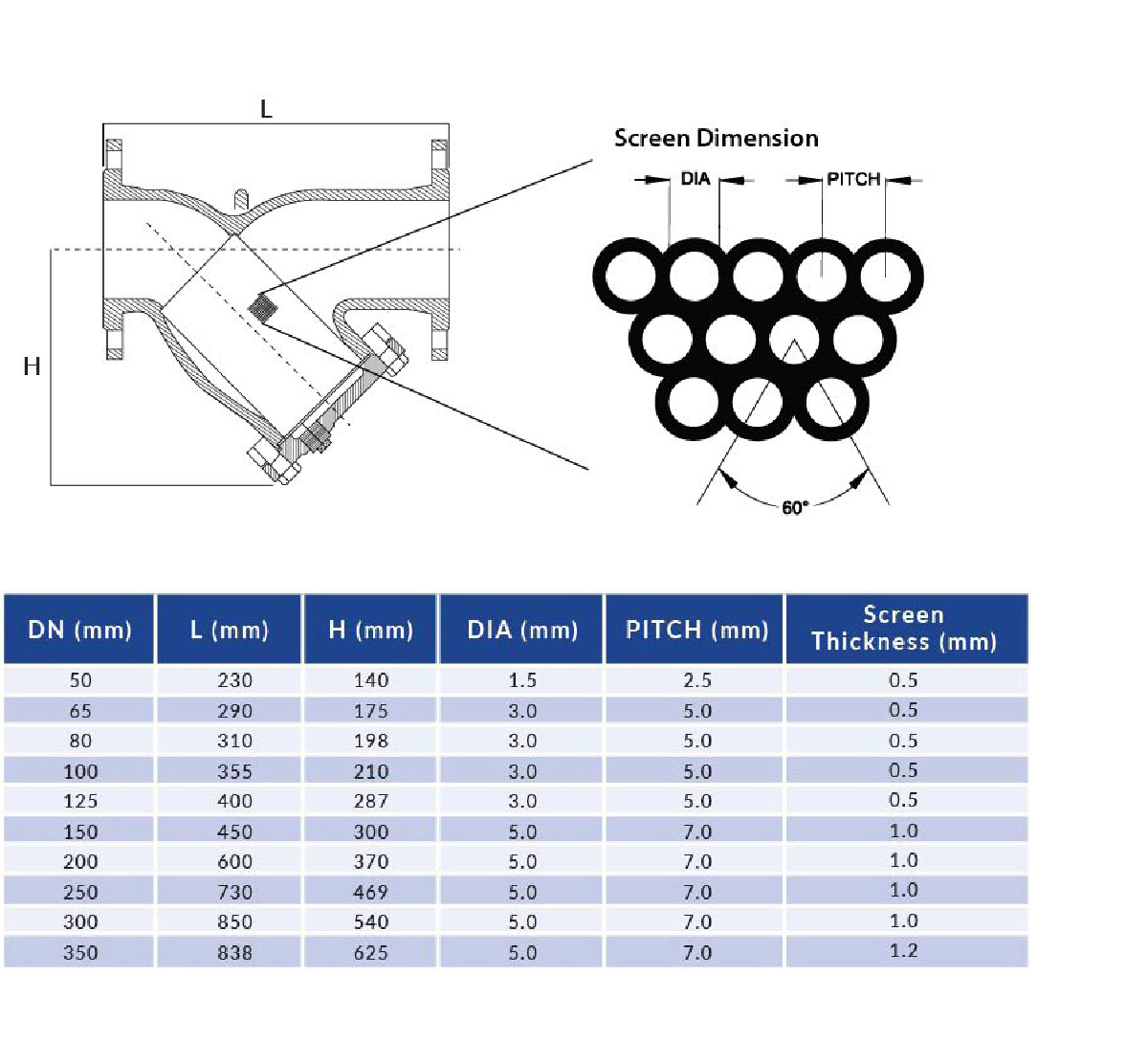

- 3Specifications & Parameters Chart

STRAINERS

Y-STRAINER

For Pipeline System, Equipments & Facility Protection

Model No, : LYE881

- 1Description

LYE Y-Strainer is designed for screen out solid materials and debris, it is commonly installed at upstream of metering system, inlet of control valves, or outlet of the pump for the protection of the important equipments in the pipeline system & facility from flow clogging, keeping the pipeline system in safe, clean and optimizing works efficiency. Advanced new design of perforated stainless steel screen for minimum cleaning, and suitable for both horizontal or vertical installation with screen position pointing downward, and for flow vertically downwards in vertical pipelines.

f

.

• Design for increasing the life span and reducing the maintenance cost of water meters & industry systems services

• For improving the reticulation for bulk meter system from Any Potential Damage Caused by Solid Materials & Debris

• Suitable for water & oil.

• Maximum temperature: < 100°C

• Working Pressure: PN16

• Shell Pressure: PN24

• Coating: Fusion Bonded Epoxy

• Sealing: EPDM.Standards

• Flange: EN 1092-2.Features

• Range of Strainer Sizes: DN50 to DN350

• Advanced new design of perforated stainless steel screen for minimum cleaning.

• Any dirt or debris accumulated can be flushed out through the drain plug - 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.