REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

AIR VALVE

SINGLE LARGE ORIFICE VALVES

Air & Vaccum Release Valves

Model No. : 254 – Non Isolating Type

Model No. : 255 – c/w Isolating Sluice Valve Type

- 1Description

LYE Single Large Orifice Air Valves, also known as air and vacuum valves, are designed to exhaust large quantities of air automatically during pipeline filling, and to admit large quantities of air when the internal pressure in the pipeline drop below atmospheric pressure. Ideal for vacuum prevention & higher venting efficiency from a system pipeline. . • For large volume of air discharging during pipeline filling while

• pressurizing & air admitting during pipeline draining while

• depressurizing• Working Pressure : 10/16 Bar • Shell Pressure : 15/24 Bar • Seat Pressure : 11/17.6 Bar • Minimum Operation Pressure : 0.5 Bar • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : JKR 20200-0097-01 • Test : EN 12266-1 • Flange : EN 1092-2 . Features • Range of Valve Sizes : DN50 to DN200 • Float Material : ABS Single Large Orifice • For vacuum prevention & higher venting efficiency from a

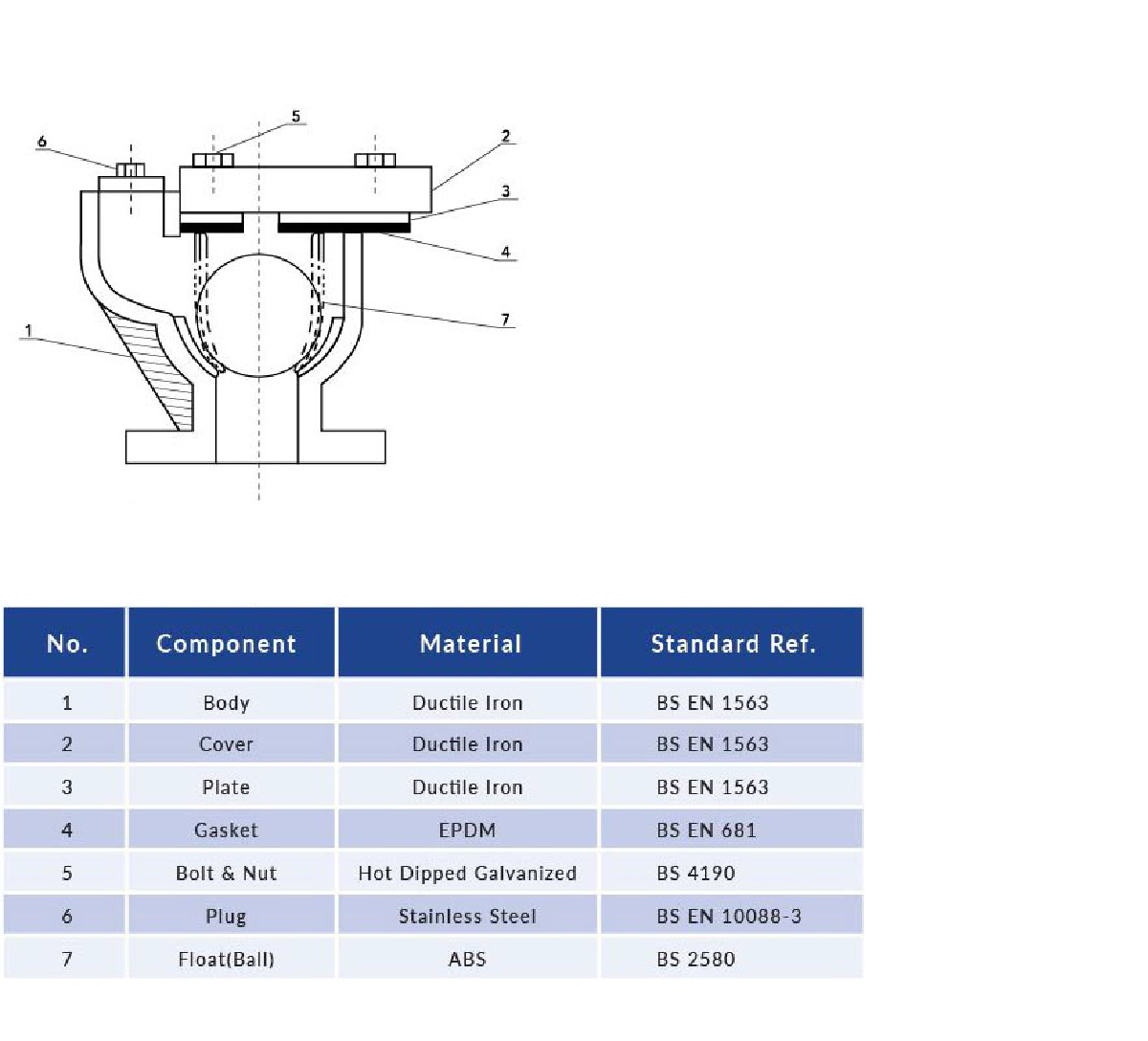

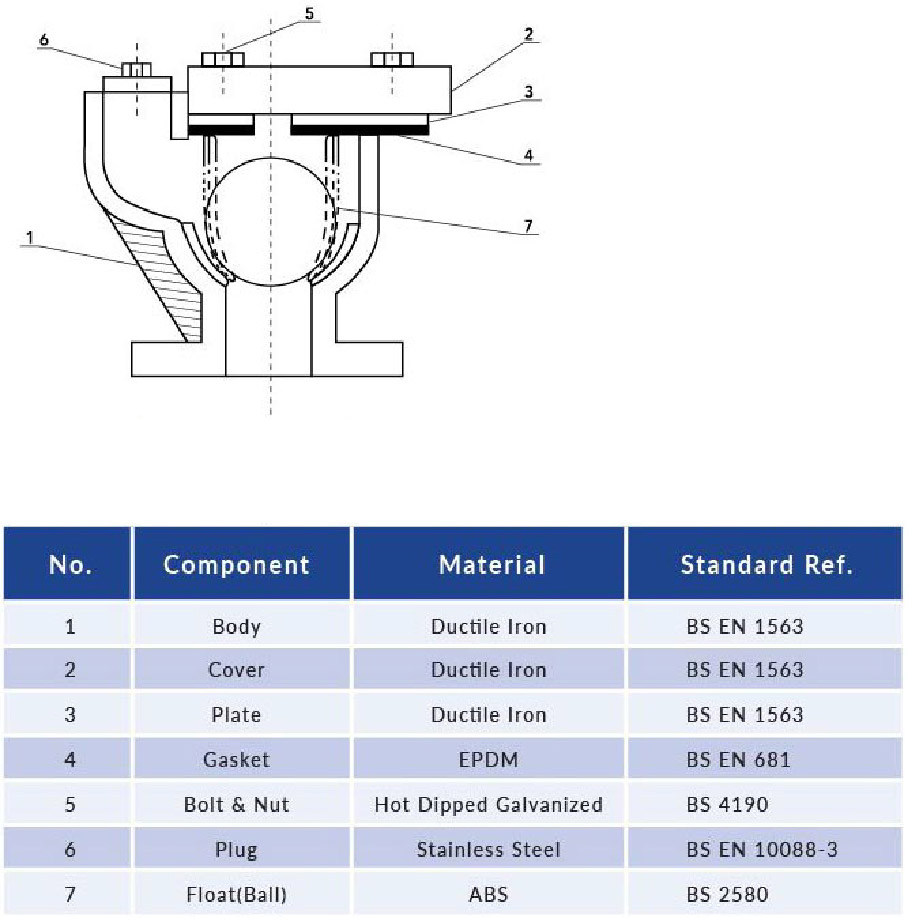

• system pipeline - 2Parts List & Materials

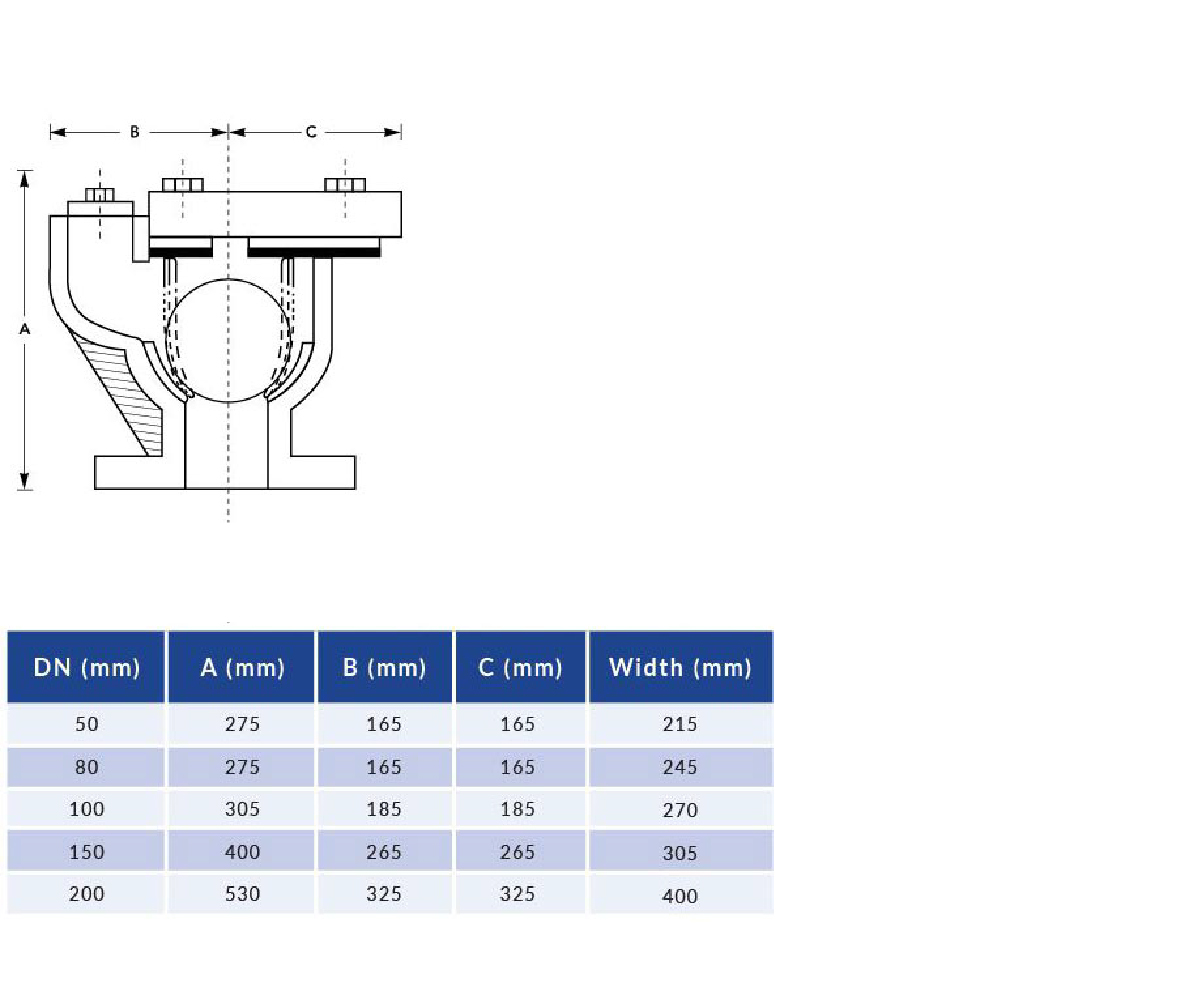

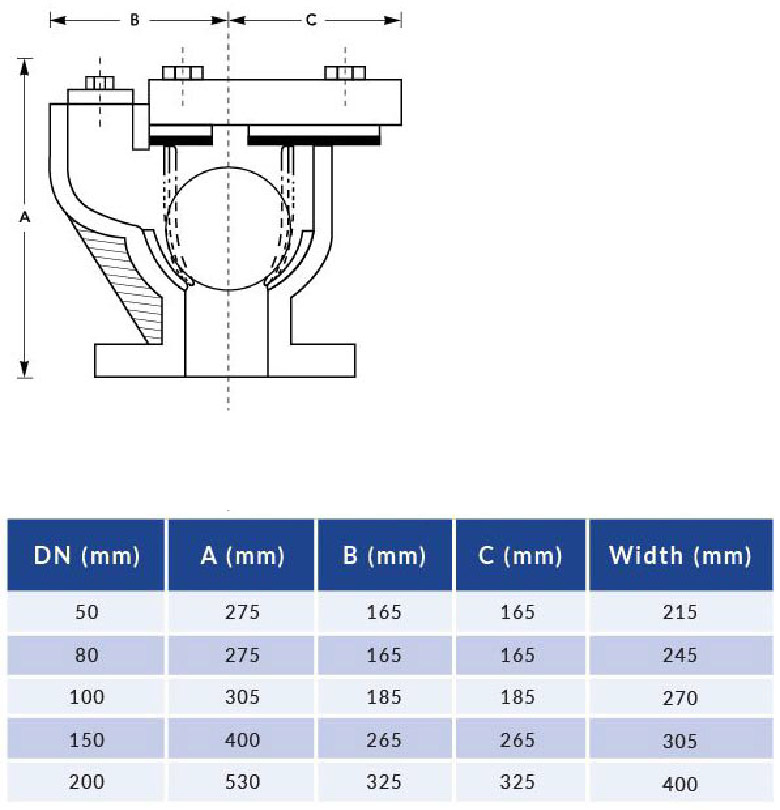

- 3Specifications & Parameters Chart

AIR VALVE

SINGLE LARGE ORIFICE VALVES

Air & Vaccum Release Valves

Model No. : 254 – Non Isolating Type

Model No. : 255 – c/w Isolating Sluice Valve Type

- 1Description

LYE Single Large Orifice Air Valves, also known as air and vacuum valves, are designed to exhaust large quantities of air automatically during pipeline filling, and to admit large quantities of air when the internal pressure in the pipeline drop below atmospheric pressure. Ideal for vacuum prevention & higher venting efficiency from a system pipeline. . • For large volume of air discharging during pipeline filling while

• pressurizing & air admitting during pipeline draining while

• depressurizing• Working Pressure : 10/16 Bar • Shell Pressure : 15/24 Bar • Seat Pressure : 11/17.6 Bar • Minimum Operation Pressure : 0.5 Bar • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : JKR 20200-0097-01 • Test : EN 12266-1 • Flange : EN 1092-2 . Features • Range of Valve Sizes : DN50 to DN200 • Float Material : ABS Single Large Orifice • For vacuum prevention & higher venting efficiency from a

• system pipeline - 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.