REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

STRAINERS

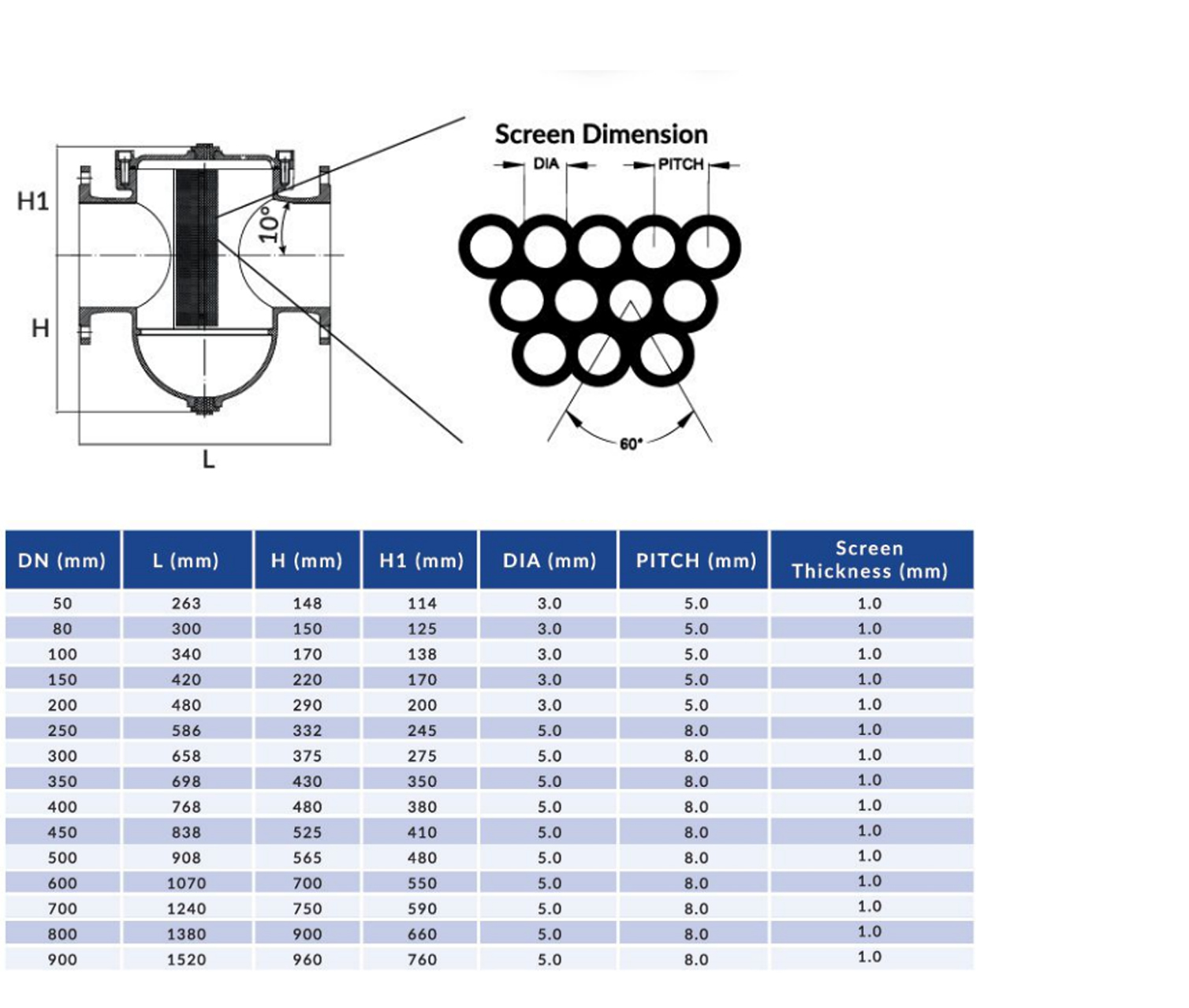

T-POT STRAINER

For System Protection & Higher Work-Optimization Efficiency

- 1Description

LYE T-Pot Strainer is a well-designed product that could effectively reduce the maintenance costs of water meter by preventing solid materials and debris that could damaging any important equipments in the pipeline system & facility from system clogging, it is commonly installed at upstream of metering system, inlet of control valves, or outlet of the pump for system protection that keeping the pipeline system in safe, clean and optimizing works efficiency. Advanced new design of perforated stainless steel screen for minimum cleaning, better coefficient and much lower head loss due to greater free straining area. In addition, Specially reinforced stainless steel bar ribs on the screen to be considered for more rigid and resistance of being destroyed or flushed out during operation.

f

- T-Pot Type is ideally designed for optimizing the maintenance & operational efficiency for both metering system and industry systems services.

- For system protection and metering inaccuracies prevention from Any Potential Damage Caused By Solid Materials & Debris.

- Suitable for water & oil.

- Maximum temperature

: < 100°C

- Working Pressure

: PN16

- Shell Pressure

: PN24

- Coating

: Fusion Bonded Epoxy

- Sealing

: EPDM

.

Standards - Design

: JKR 20200–0100–01 - Flange

: EN 1092-2

.

Features - Range of Strainer Sizes

: DN50 to DN900 - T-pot Type Strainer allows installation of air release valve for air bubbles releasing.

- Specially reinforced stainless steel bar ribs on the screen to be considered for more rigid and resistance of being destroyed or flushed out during operation.

- Any dirt or debris accumulated can be flushed out through the drain plug.

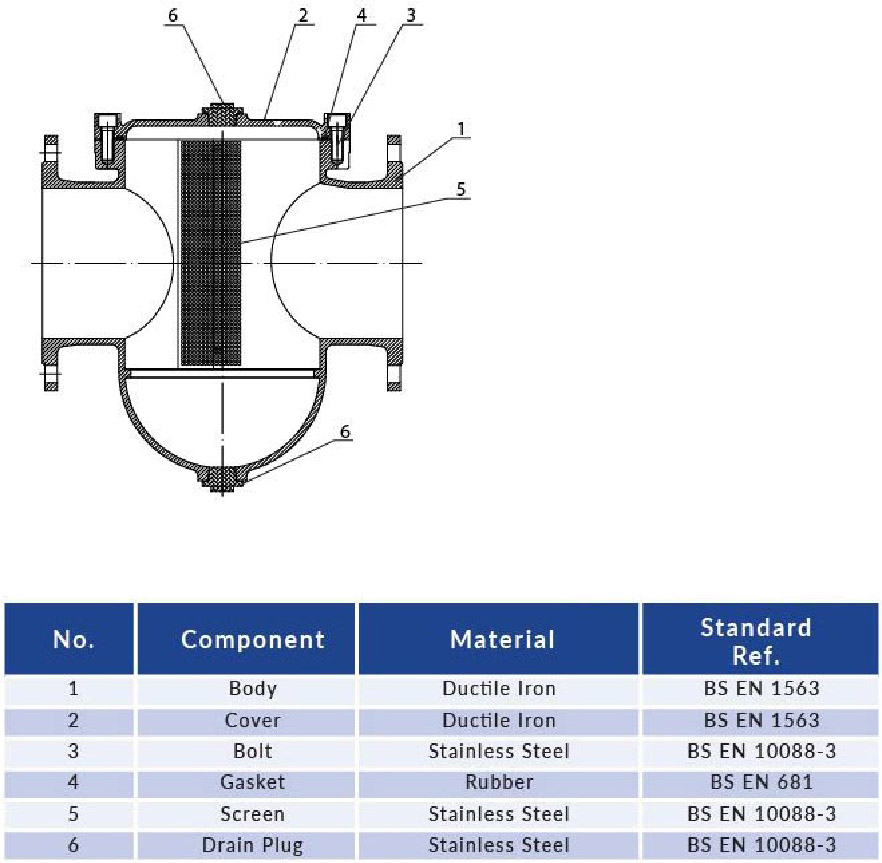

- 2Parts List & Materials

- 3Specifications & Parameters Chart

STRAINERS

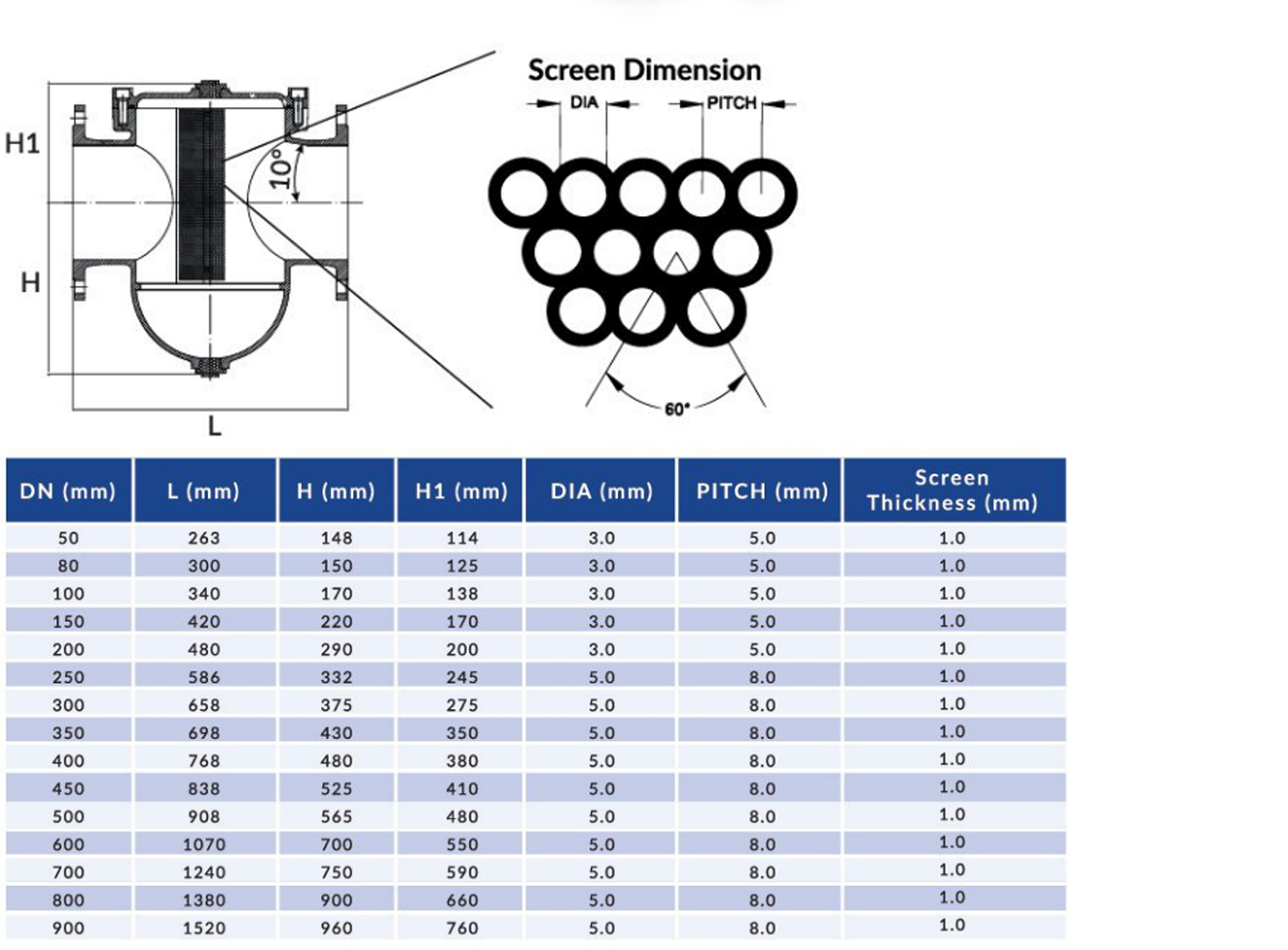

T-POT STRAINER

For System Protection & Higher Work-Optimization Efficiency

- 1Description

LYE T-Pot Strainer is a well-designed product that could effectively reduce the maintenance costs of water meter by preventing solid materials and debris that could damaging any important equipments in the pipeline system & facility from system clogging, it is commonly installed at upstream of metering system, inlet of control valves, or outlet of the pump for system protection that keeping the pipeline system in safe, clean and optimizing works efficiency. Advanced new design of perforated stainless steel screen for minimum cleaning, better coefficient and much lower head loss due to greater free straining area. In addition, Specially reinforced stainless steel bar ribs on the screen to be considered for more rigid and resistance of being destroyed or flushed out during operation.

f

- T-Pot Type is ideally designed for optimizing the maintenance & operational efficiency for both metering system and industry systems services.

- For system protection and metering inaccuracies prevention from Any Potential Damage Caused By Solid Materials & Debris.

- Suitable for water & oil.

- Maximum temperature

: < 100°C

- Working Pressure

: PN16 - Shell Pressure

: PN24

- Coating

: Fusion Bonded Epoxy

- Sealing

: EPDM

.

Standards - Design

: JKR 20200–0100–01 - Flange

: EN 1092-2

.

Features - Range of Strainer Sizes

: DN80 to DN900 - T-pot Type Strainer allows installation of air release valve for air bubbles releasing.

- Specially reinforced stainless steel bar ribs on the screen to be considered for more rigid and resistance of being destroyed or flushed out during operation.

- Any dirt or debris accumulated can be flushed out through the drain plug.

- 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.