REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

AIR VALVE

“AEROKINETIC”, DOUBLE ORIFICE KINETIC

Double Orifice Kinetic Air Valve

Model No. : 358 – ABS Float Type

Model No. : 358A – Stainless Steel Float Type

- 1Description

LYE Double Orifice Kinetic Air Valve design for air discharge, air intake & air release functions, a high-performance combination air valve that’s meets all applications and installation parameters regardless of piping material. The Aerokinetic Air Valve with cylinder shape main float is ideal for the high-volume of air release and intake in piping systems has minimum moving parts thus ensuring long-terms reliability. Technically, LYE “Aerokinetic” is designed for enabling optimun air discharge & admission capacities to be achieved, and will not close prematurely while large volume of air is being released from a pipeline. . • Small Orifice

f

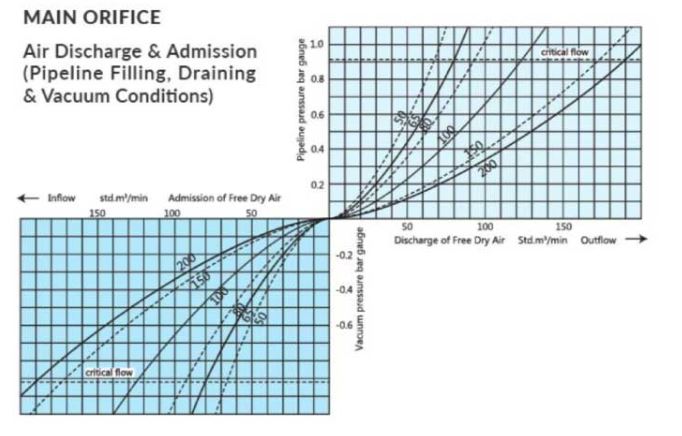

: Automatic air release small pockets of accumulated air from pipeline operate under pressure• Main Orifice

f

f

f

f

: For large volume of air discharging during pipeline filling while pressurizing & air admitting during pipeline draining while depressurizing for vacuum prevention• Working Pressure : 10/16 Bar • Shell Pressure : 15/24 Bar • Seat Pressure : 11/17.6 Bar • Minimum Operation Pressure : 0.5 Bar • Working Temperature : 0.6°C°- 52°C (ALT + 0176 = °) • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Test : EN 12266-1 • Flange : EN 1092-2 . Features • Range of Valve Sizes : DN50 to DN150 • Float Material : ABS Or Stainless -Steel • Unique Design Prevents Premature Seating of Float • Cylinder Shape Main Float Design Minimize Float Movement - 2Parts List & Materials

- 3Specifications & Parameters Chart

- 4Further Information

.

.

.

AIR VALVE

“AEROKINETIC”, DOUBLE ORIFICE KINETIC

Double Orifice Kinetic Air Valve

Model No. : 358 – ABS Float Type

Model No. : 358A – Stainless Steel Float Type

- 1Description

LYE Double Orifice Kinetic Air Valve design for air discharge, air intake & air release functions, a high-performance combination air valve that’s meets all applications and installation parameters regardless of piping material. The Aerokinetic Air Valve with cylinder shape main float is ideal for the high-volume of air release and intake in piping systems has minimum moving parts thus ensuring long-terms reliability. Technically, LYE “Aerokinetic” is designed for enabling optimun air discharge & admission capacities to be achieved, and will not close prematurely while large volume of air is being released from a pipeline. . • Small Orifice

f

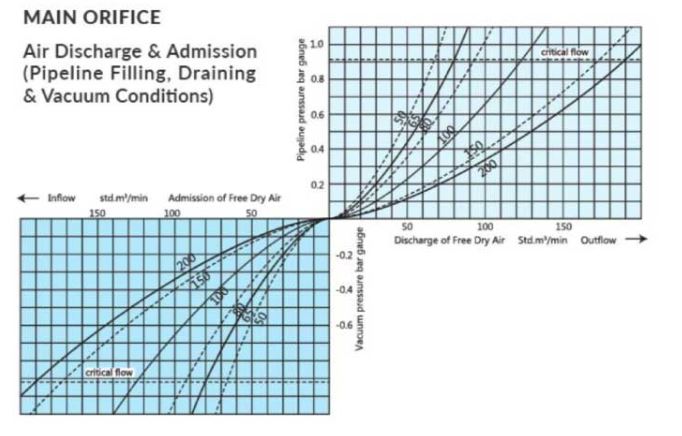

: Automatic air release small pockets of accumulated air from pipeline operate under pressure• Main Orifice

f

f

f

f

: For large volume of air discharging during pipeline filling while pressurizing & air admitting during pipeline draining while depressurizing for vacuum prevention• Working Pressure : 10/16 Bar • Shell Pressure : 15/24 Bar • Seat Pressure : 11/17.6 Bar • Minimum Operation Pressure : 0.5 Bar • Working Temperature : 0.6°C°- 52°C (ALT + 0176 = °) • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Test : EN 12266-1 • Flange : EN 1092-2 . Features • Range of Valve Sizes : DN50 to DN150 • Float Material : ABS Or Stainless -Steel • Unique Design Prevents Premature Seating of Float • Cylinder Shape Main Float Design Minimize Float Movement - 2Parts List & Materials

- 3Specifications & Parameters Chart

- 4Further Information

.

.

.

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.