REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1

CLAMPS & SADDLES

DIRECT DRILL & TAP NARROW SADDLE FOR AC, MS & DI

Narrow Saddle Body & Tapping Internally Threaded

Model No. : LYE775

- 1Description

LYE Ductile Iron Ferrous Saddle for DI & AC pipes is designed for connecting branch pipeline to DI, AC & MS pipes with same size range at the main pipeline by providing a surface sealing around the cutting hole on the pipe with leak-tight connection. Ferrous Saddle is used as service clamp which it is attached directly 360? around the pipe surface in order to provide support for the pipe to distribute stresses evenly on the surface as well as at the tapping hole area. LYE Ductile Iron Saddle Solution is designed to provide full support around the circumference of the pipe with sufficient lengths to furnish satisfactory sealing and preventing pipe movements . • Complete With Ferrule For Making Service Connections & Direct

• Under Pressure Tapping Of DI, AC & MS Pipes In Water Mains• Narrow Saddle Body & Tapping Internally Threaded On Rigid

• & Non-Plastic Pipeline.• Tapping Outlet Sizes From Small Which Supply Residential

• Homes To Large Outlets For Commercial & Industial Users.• Designed & Sized To Provide Full Support Around The

• Circumference Of The Pipe Common OD Systems• Working Pressure : PN 16 • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : Modified SPESIFIKASI JKR 20200-0184-04 • Test : Modified SPESIFIKASI JKR 20200-0184-04 & EN12266 -1• Threads : MS ISO 7 / BS 21 • For Ductile Iron Pipe : BS EN 545 / ISO 2531 / MS 1919 • For Mild Steel Pipe : BS 534 / SPAN TS 21827 / JKR • For AC Pipe : BS EN 512 / MS 712 . Features • Range of Ferrous Saddle for DI

• & AC Pipes Sizes: DN80 to DN300 • Tapping Outlets Size Ranges : ½”, ¾” to 1″ BSP • Designed For Easy Saddle Mounting, Maintenance Free & Longevity • Narrow Saddle Body Furnishing Satisfactory Sealing & Preventing

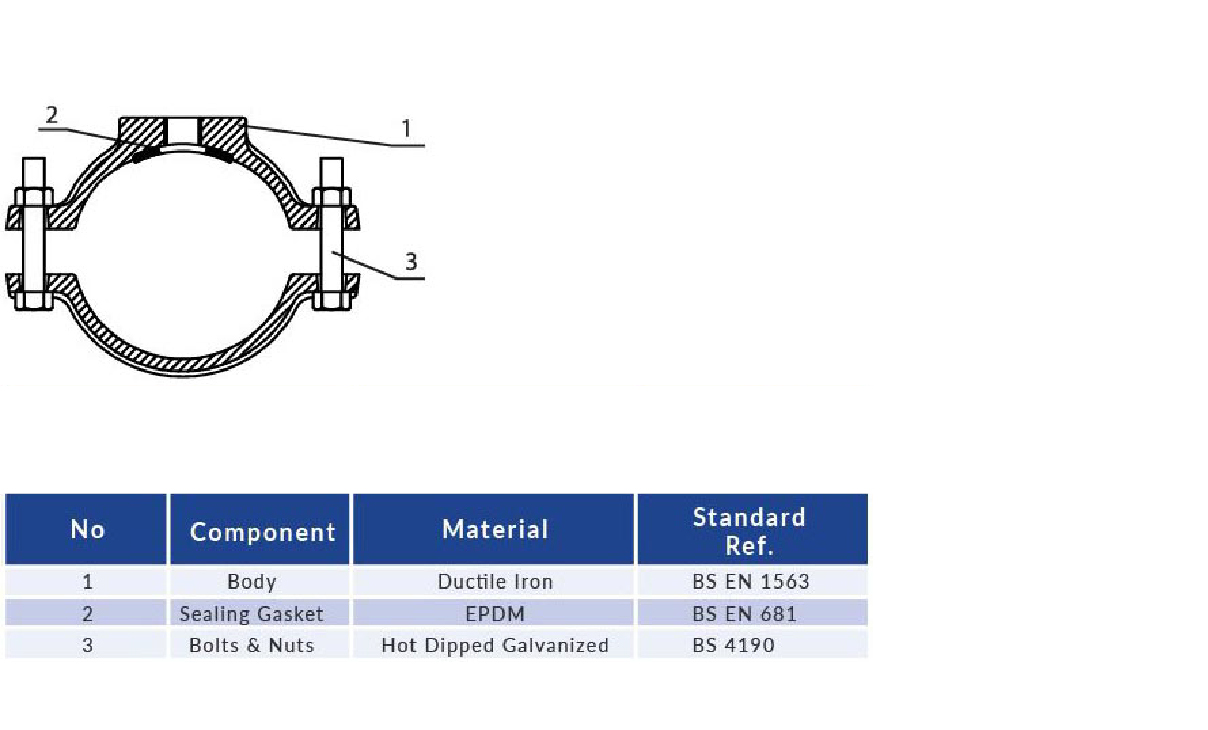

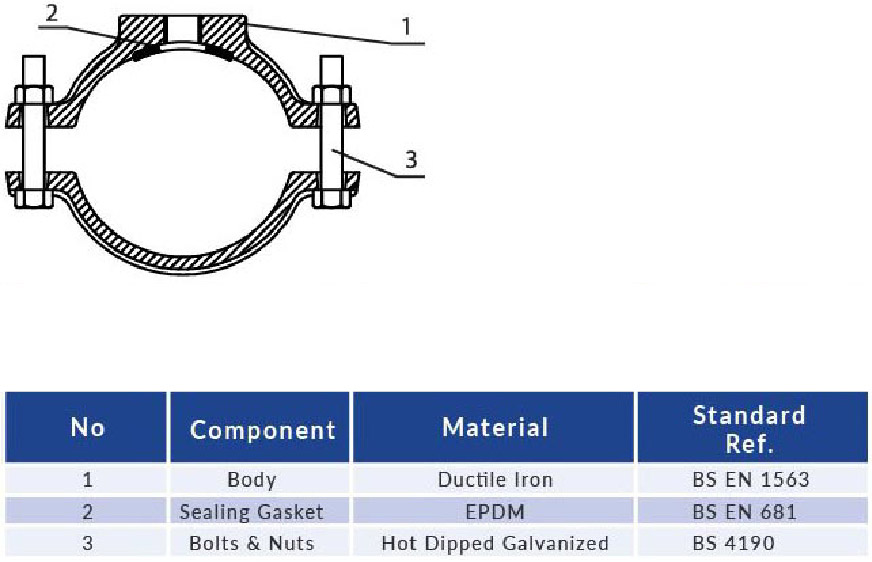

• Pipe Movements On Rigid & Non-plastic Pipeline. - 2Parts List & Materials

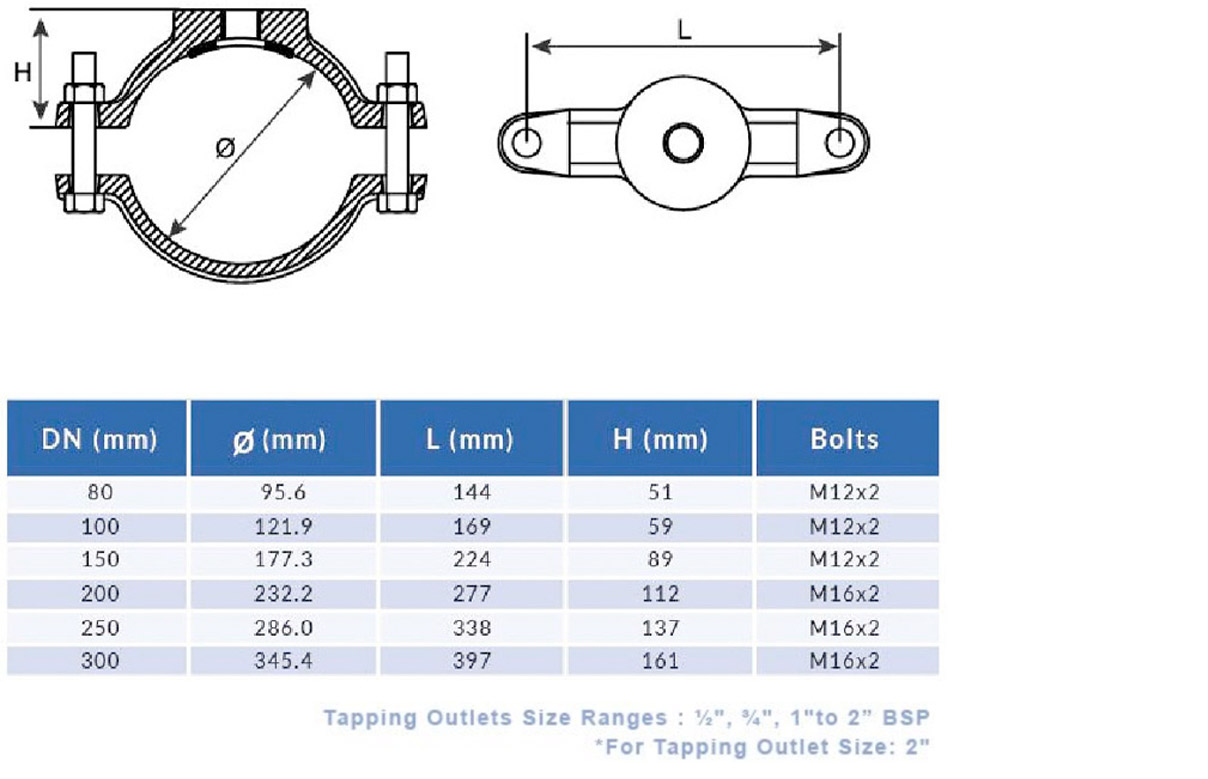

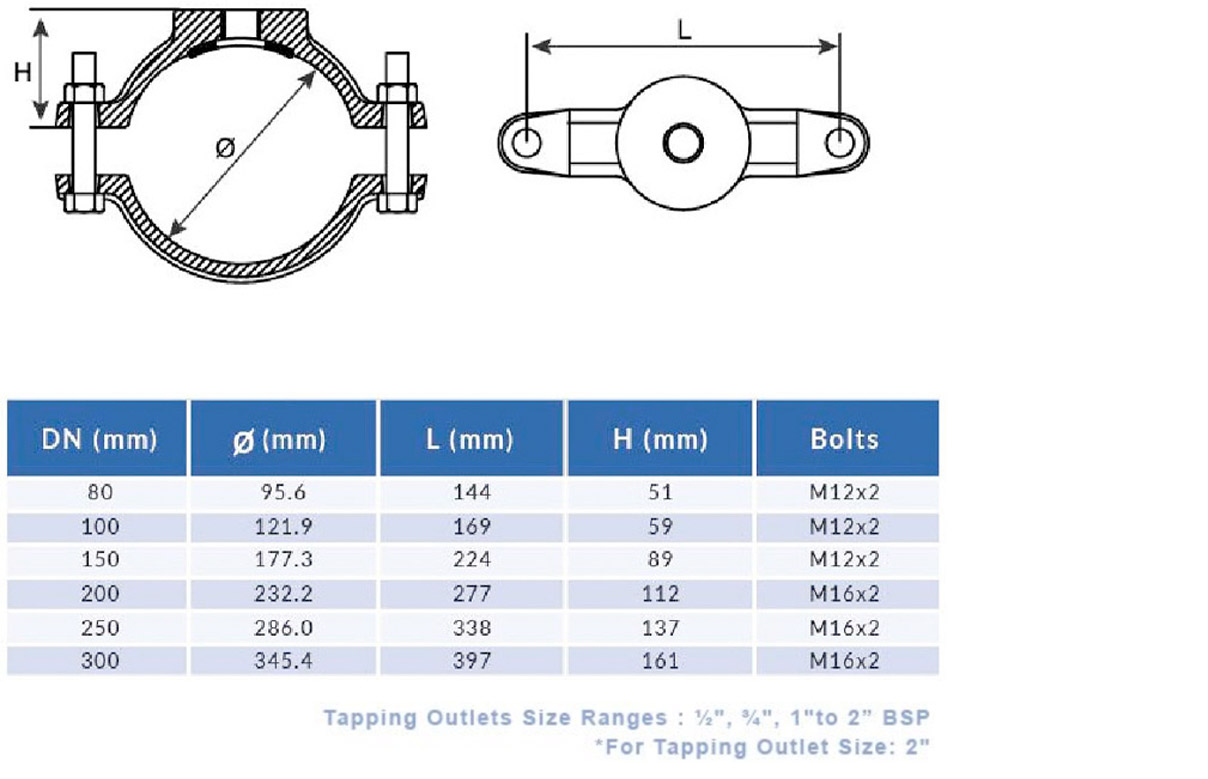

- 3Specifications & Parameters Chart

CLAMPS & SADDLES

DIRECT DRILL & TAP NARROW SADDLE FOR AC, MS & DI

Narrow Saddle Body & Tapping Internally Threaded

Model No. : LYE775

- 1Description

LYE Ductile Iron Ferrous Saddle for DI & AC pipes is designed for connecting branch pipeline to DI, AC & MS pipes with same size range at the main pipeline by providing a surface sealing around the cutting hole on the pipe with leak-tight connection. Ferrous Saddle is used as service clamp which it is attached directly 360? around the pipe surface in order to provide support for the pipe to distribute stresses evenly on the surface as well as at the tapping hole area. LYE Ductile Iron Saddle Solution is designed to provide full support around the circumference of the pipe with sufficient lengths to furnish satisfactory sealing and preventing pipe movements . • Complete With Ferrule For Making Service Connections & Direct

• Under Pressure Tapping Of DI, AC & MS Pipes In Water Mains• Narrow Saddle Body & Tapping Internally Threaded On Rigid

• & Non-Plastic Pipeline.• Tapping Outlet Sizes From Small Which Supply Residential

• Homes To Large Outlets For Commercial & Industial Users.• Designed & Sized To Provide Full Support Around The

• Circumference Of The Pipe Common OD Systems• Working Pressure : PN 16 • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : Modified SPESIFIKASI JKR 20200-0184-04 • Test : Modified SPESIFIKASI JKR 20200-0184-04 & EN12266 -1• Threads : MS ISO 7 / BS 21 • For Ductile Iron Pipe : BS EN 545 / ISO 2531 / MS 1919 • For Mild Steel Pipe : BS 534 / SPAN TS 21827 / JKR • For AC Pipe : BS EN 512 / MS 712 . Features • Range of Ferrous Saddle for DI

• & AC Pipes Sizes: DN80 to DN300 • Tapping Outlets Size Ranges : ½”, ¾” to 1″ BSP • Designed For Easy Saddle Mounting, Maintenance Free & Longevity • Narrow Saddle Body Furnishing Satisfactory Sealing & Preventing

• Pipe Movements On Rigid & Non-plastic Pipeline. - 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1