REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1

CHECK VALVES

DOUBLE DOOR WAFER TYPE

Check Valve For Water Pumping System

- 1Description

LYE Double Door Wafer Type check valve, the dual disc check valve is light weight and its compact design having great installation advantages with easy disassembly, cost efficient and small occupancy of space. Good Non-Slam operation with short linear disc stroke closing by torsion spring. Wafer type check valve likes LYE Wafer type butterfly valve fit the majority of flange standards, connecting between 2 pipe flange. . • Great Installation Advantages with small volume, light weight,

• compact structure & easy maintenance• Working Pressure : 10/16 bar • Shell Pressure : 15/24 bar • Seat Pressure : 11/17.6 bar • Temperature Range : 0°C – 80°C • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Test : BS EN 12266 • For Connecting End : BS EN 1092 PN10/PN16, JIS B2212 10K, BS 10 Table D/E, AS 2129 Table E. Features • Range of Valve Sizes : DN50 to DN600 • Universal flange connection to BS EN 1092 PN10/16, ASME B16.1

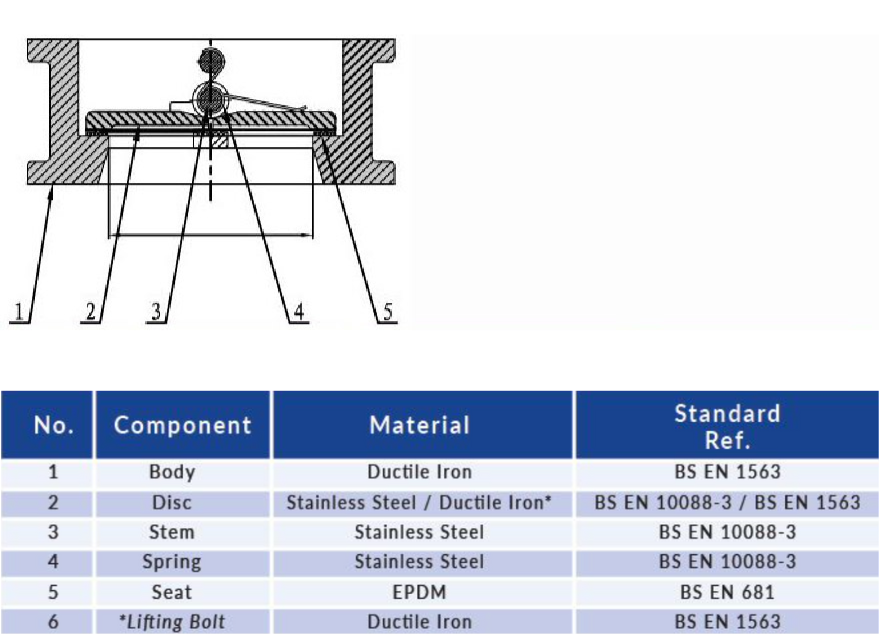

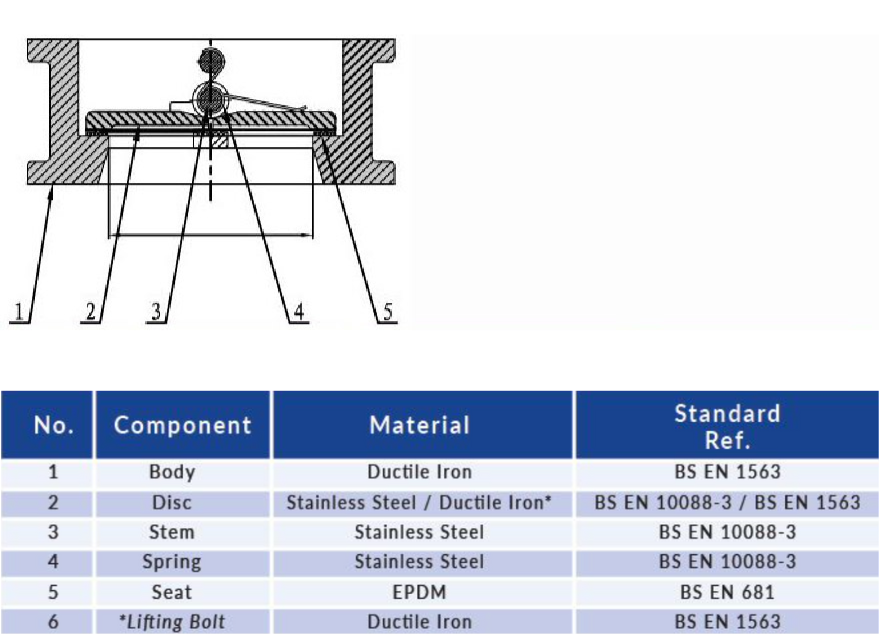

• CL125, ASME B16.5 CL150, JIS 10K, BS Table E/D• For vertical pipeline installation in delivering upwards flow - 2Parts List & Materials

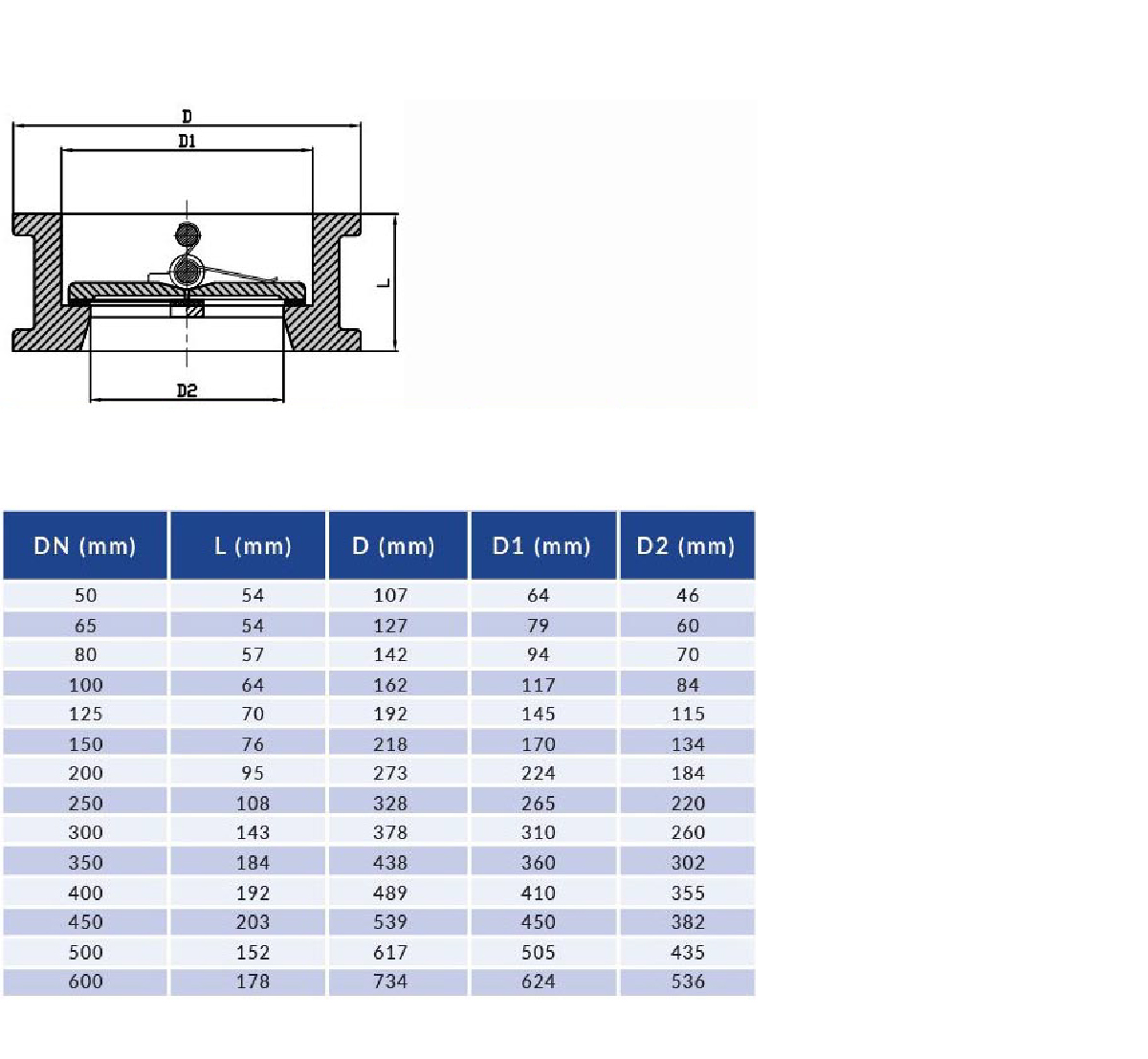

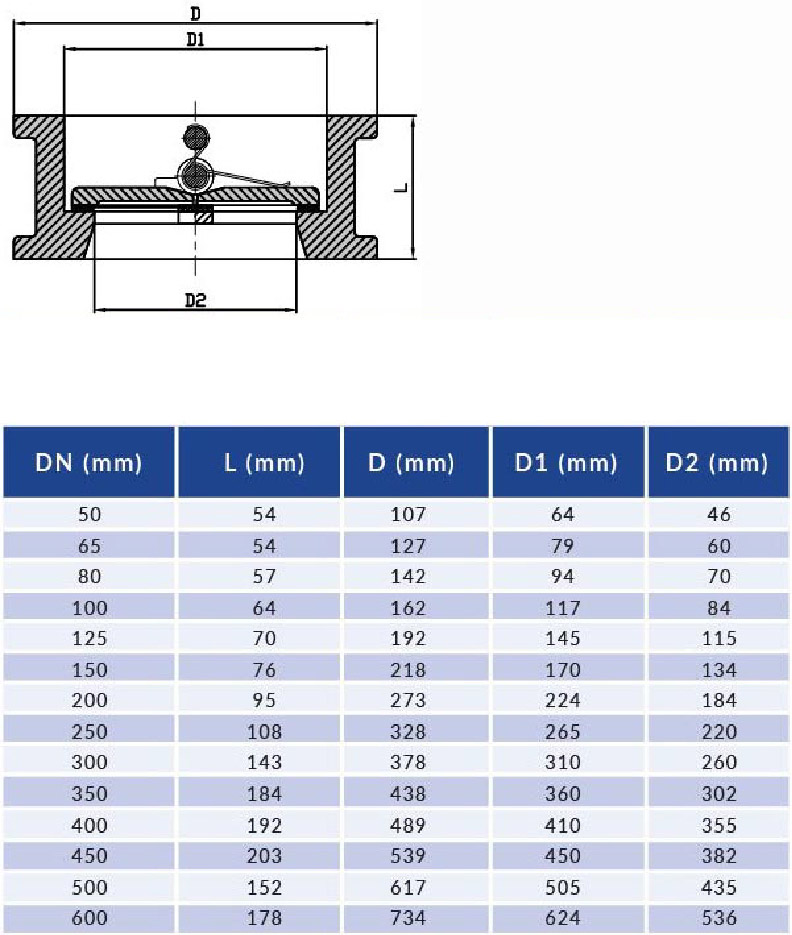

- 3Specifications & Parameters Chart

CHECK VALVES

DOUBLE DOOR WAFER TYPE

Check Valve For Water Pumping System

- 1Description

LYE Double Door Wafer Type check valve, the dual disc check valve is light weight and its compact design having great installation advantages with easy disassembly, cost efficient and small occupancy of space. Good Non-Slam operation with short linear disc stroke closing by torsion spring. Wafer type check valve likes LYE Wafer type butterfly valve fit the majority of flange standards, connecting between 2 pipe flange. . • Great Installation Advantages with small volume, light weight,

• compact structure & easy maintenance• Working Pressure : 10/16 bar • Shell Pressure : 15/24 bar • Seat Pressure : 11/17.6 bar • Temperature Range : 0°C – 80°C • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Test : BS EN 12266 • For Connecting End : BS EN 1092 PN10/PN16, JIS B2212 10K, BS 10 Table D/E, AS 2129 Table E. Features • Range of Valve Sizes : DN50 to DN600 • Universal flange connection to BS EN 1092 PN10/16, ASME B16.1

• CL125, ASME B16.5 CL150, JIS 10K, BS Table E/D• For vertical pipeline installation in delivering upwards flow - 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1