REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

BUTTERFLY VALVE

DOUBLE ECCENTRIC FLANGED

Worm Gear Operated With Handwheel

- 1Description

LYE Double Eccentric Flanged Butterfly Valve, high performance double offset eccentric type, quarter-turn operating butterfly valve is used to start, stop, and regulate fluid movement. Double offset configuration with 2 offsets both located not in the center line, disc does not touch rubber seal in open position. The disc is of a stream line shape and so loss of water head at the full opening of valve is minimize, and having smooth surface with little resistance to flow. A one piece rubber disc edge seating provide reliably sealing performance and ensure longevity. . • For precise operation and longevity with less friction experienced

• during valve operating• Working Pressure : 10/16 Bar • Disc Strength : 15/24 Bar • Seat Test Pressure : 11/17.6 Bar • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : BS EN 593 • Flange : BS EN 1092-2 • Top Flange : ISO 5211 . Features • Range of Valve Sizes : DN50 to DN2400 • Standard Valve Actuator : Worm Gear With Handwheel ( >=DN100 Lever Type ) • High service life due to low wear and tear on rubber sealing • Excellent performance of flow regulating at delivery main for

• pumping station. - 2Parts List & Materials

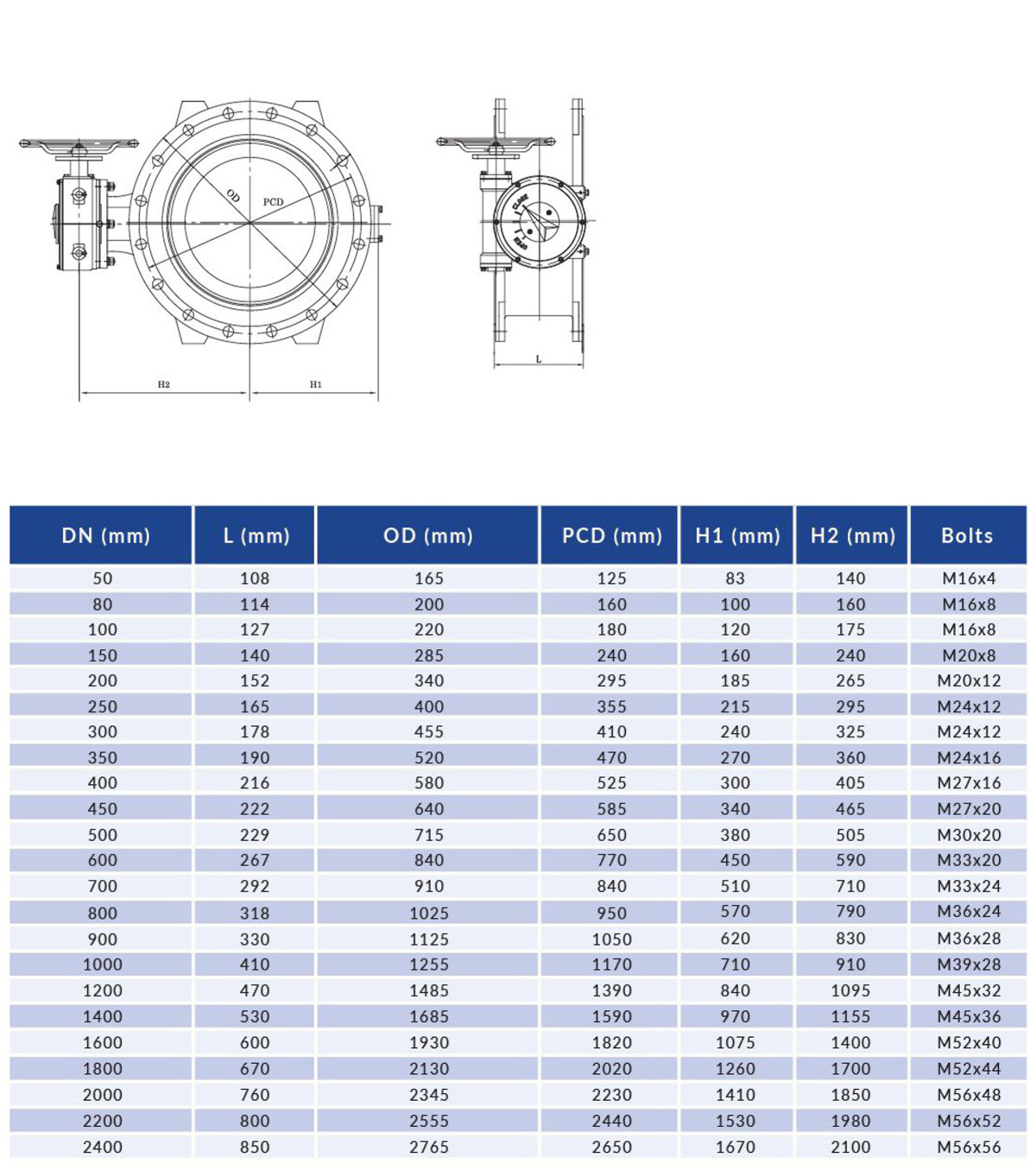

- 3Specifications & Parameters Chart

Note: Technical data provided is indicative only and may be subject to change without prior notice

BUTTERFLY VALVE

DOUBLE ECCENTRIC FLANGED

Worm Gear Operated With Handwheel

- 1Description

LYE Double Eccentric Flanged Butterfly Valve, high performance double offset eccentric type, quarter-turn operating butterfly valve is used to start, stop, and regulate fluid movement. Double offset configuration with 2 offsets both located not in the center line, disc does not touch rubber seal in open position. The disc is of a stream line shape and so loss of water head at the full opening of valve is minimize, and having smooth surface with little resistance to flow. A one piece rubber disc edge seating provide reliably sealing performance and ensure longevity. . • For precise operation and longevity with less friction experienced

• during valve operating• Working Pressure : 10/16 Bar • Disc Strength : 15/24 Bar • Seat Test Pressure : 11/17.6 Bar • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : BS EN 593 • Flange : BS EN 1092-2 • Top Flange : ISO 5211 . Features • Range of Valve Sizes : DN50 to DN2400 • Standard Valve Actuator : Worm Gear With Handwheel ( >=DN100 Lever Type ) • High service life due to low wear and tear on rubber sealing • Excellent performance of flow regulating at delivery main for

• pumping station. - 2Parts List & Materials

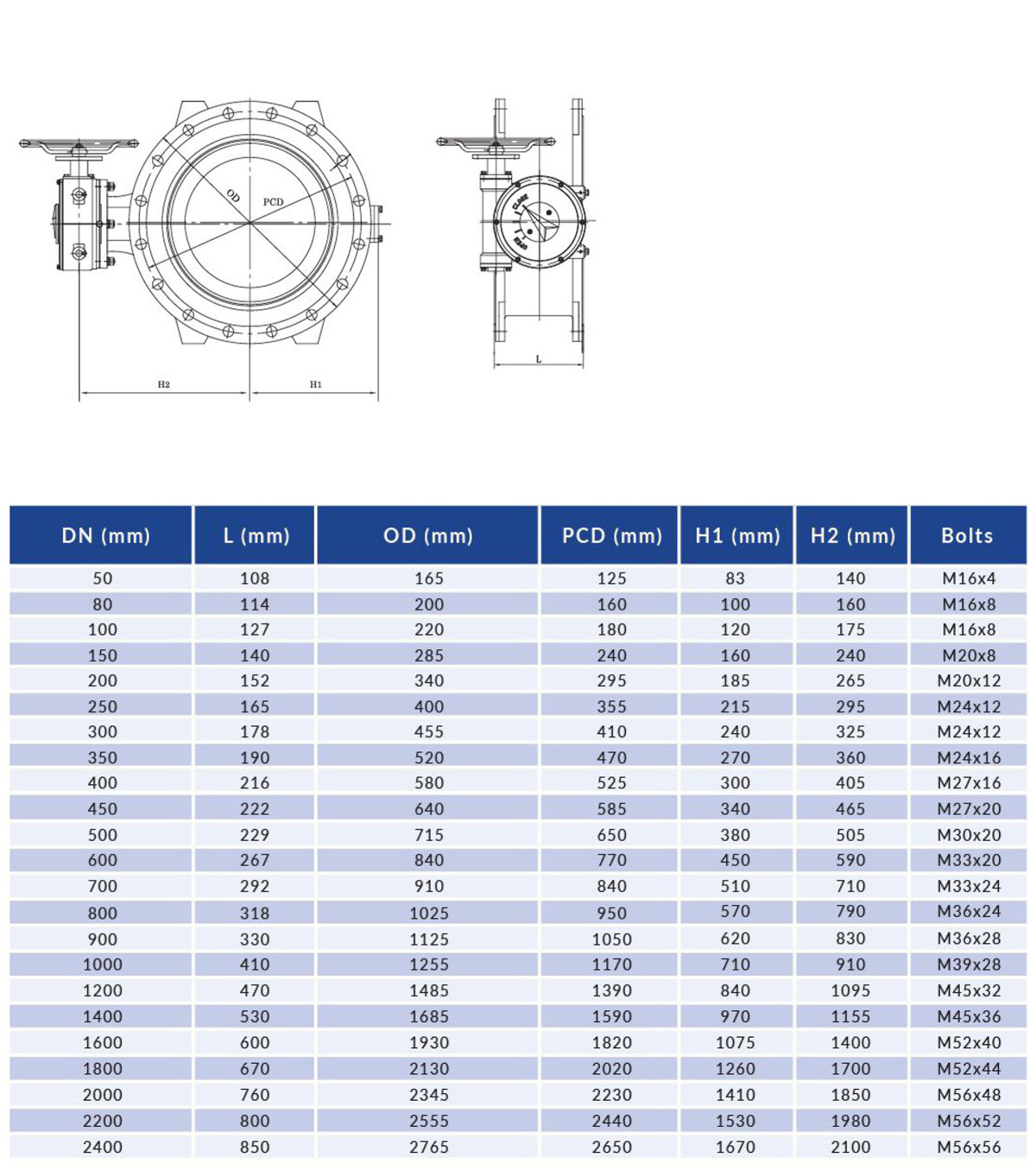

- 3Specifications & Parameters Chart

Note: Technical data provided is indicative only and may be subject to change without prior notice

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.