REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1

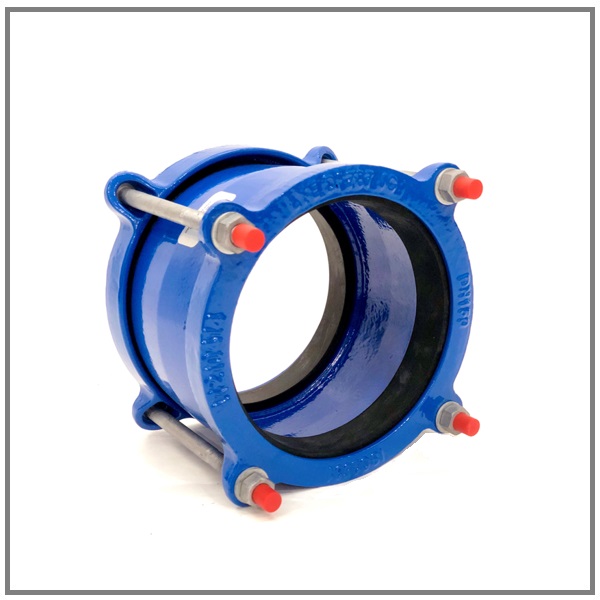

FLEXIBLE JOINTS

MECHANICAL COUPLING FOR DI

Non-Restraint Straight Couplings for Ductile Iron Pipe

Model No. : 787

- 1Description

LYE Mechanical Coupling is designed to provide a quick, leak free and reliable method of connecting plain ended Ductile Iron ( ISO 2531 / BS EN 545) and other rigid pipes with similar outside diameters. Wedge gasket design allowing various pipe preassembled within OD tolerance, +1 -3 mm and compressing to fit for maximun sealing. Flexible & straight coupling design is ideal for simple and easy underground installation, as its accommodate angularity between pipes, allowing normal pipeline movement caused by ground settlement. . • Flexible Couplings for connecting plain ended Ductile Iron and

• other rigid pipes with similar outside diameters.• Ideal for pipeline repair by cut and new pipe replacement method. • Working Pressure : PN16 • Coating : Fusion Bonded Epoxy • Sealing : EPDM • Angular Deflection : ± 3° . Standards • Design : SPESIFIKASI JKR 20200-0048-99 • Test : EN 12266-1 • For Ductile Iron Pipe : BS EN 545 / ISO 2531 / MS 1919 / DIN 28601 • For Mild Steel Pipe ( >=DN300 ) : BS 534 / SPAN TS 21827 / AS 1579 . Features • Range of Coupling Sizes : DN80 to DN800 • Wedge Gasket Type allow OD tolerance +1-3mm for water Sealing. • Flexible jointing solution for quick & easy installation of rigid

• pipe materials• Long Collar with 225mm Body Sleeve for better prevevention of pipe-pull out - 2Parts List & Materials

- 3Specifications & Parameters Chart

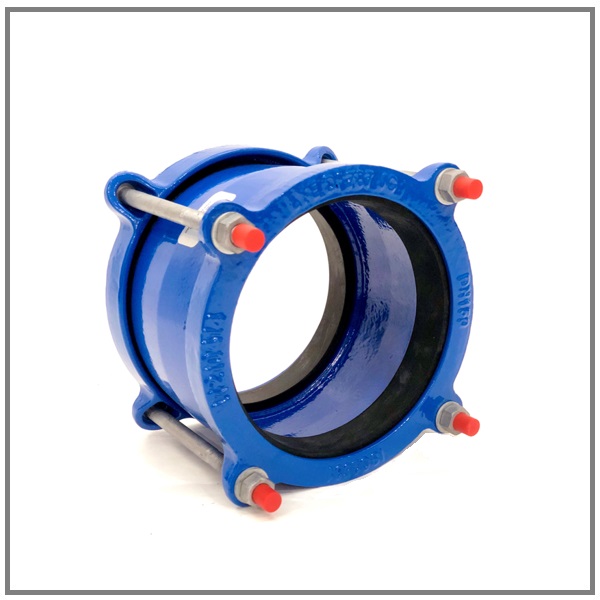

FLEXIBLE JOINTS

MECHANICAL COUPLING FOR DI

Non-Restraint Straight Couplings for Ductile Iron Pipe

Model No. : 787

- 1Description

LYE Mechanical Coupling is designed to provide a quick, leak free and reliable method of connecting plain ended Ductile Iron ( ISO 2531 / BS EN 545) and other rigid pipes with similar outside diameters. Wedge gasket design allowing various pipe preassembled within OD tolerance, +1 -3 mm and compressing to fit for maximun sealing. Flexible & straight coupling design is ideal for simple and easy underground installation, as its accommodate angularity between pipes, allowing normal pipeline movement caused by ground settlement. . • Flexible Couplings for connecting plain ended Ductile Iron and

• other rigid pipes with similar outside diameters.• Ideal for pipeline repair by cut and new pipe replacement method. • Working Pressure : PN16 • Coating : Fusion Bonded Epoxy • Sealing : EPDM • Angular Deflection : ± 3° . Standards • Design : SPESIFIKASI JKR 20200-0048-99 • Test : EN 12266-1 • For Ductile Iron Pipe : BS EN 545 / ISO 2531 / MS 1919 / DIN 28601 • For Mild Steel Pipe ( >=DN300 ) : BS 534 / SPAN TS 21827 / AS 1579 . Features • Range of Coupling Sizes : DN80 to DN800 • Wedge Gasket Type allow OD tolerance +1-3mm for water Sealing. • Flexible jointing solution for quick & easy installation of rigid

• pipe materials• Long Collar with 225mm Body Sleeve for better prevevention of pipe-pull out - 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1