REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1

CHECK VALVES

RUBBER FLAP TYPE

Non-Slam Type Swing Check Valve

- 1Description

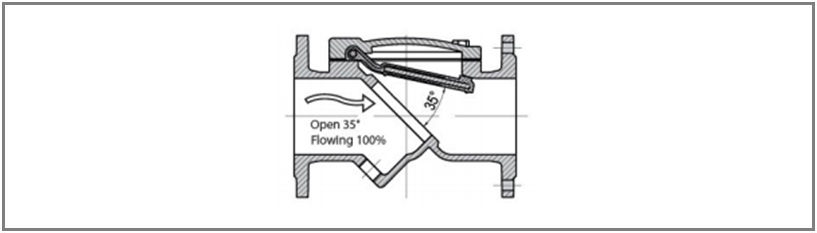

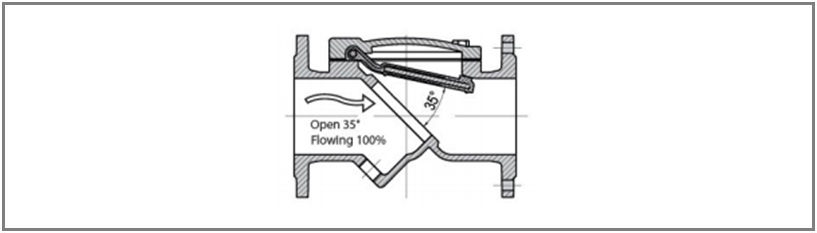

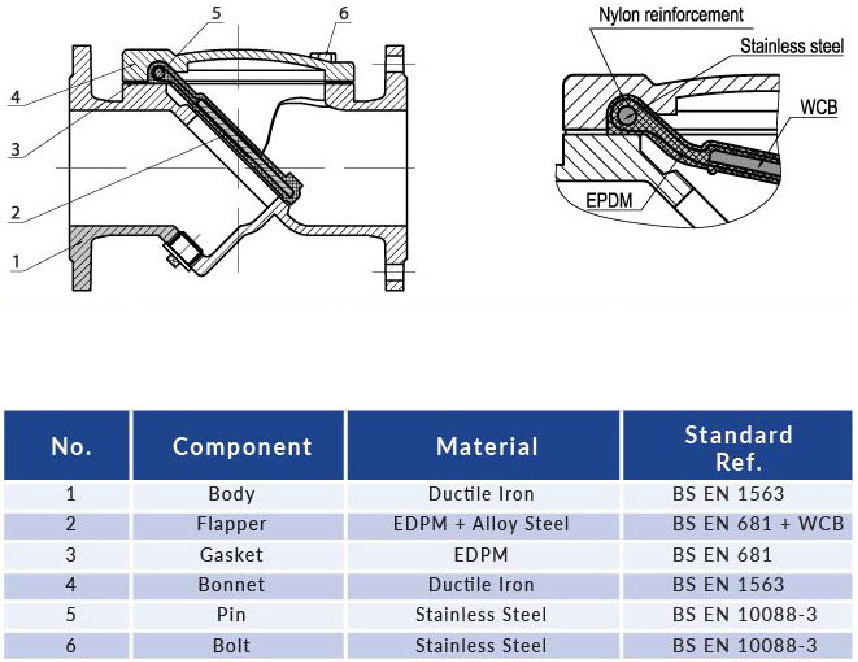

LYE Ductile Iron Rubber Flap Type Check Valve, also known as non-return swing check valves, are the most common type of check valves used. Non-slam type check valve is of a streamline design with only one moving part, the flexible disc, and body seat at a 45° angle to minimize disc travel. The disc is of one-piece construction, precision moulded with an integral o-ring type sealing surface, and contain alloy steel and nylon reinforcement in the flexible hinge area. The flex portion of the disc shall be warranted for 25 years against tear-off. Non-slam closing characteristics is provided through a short 35° disc stroke suitable for dynamic of the pumping system.

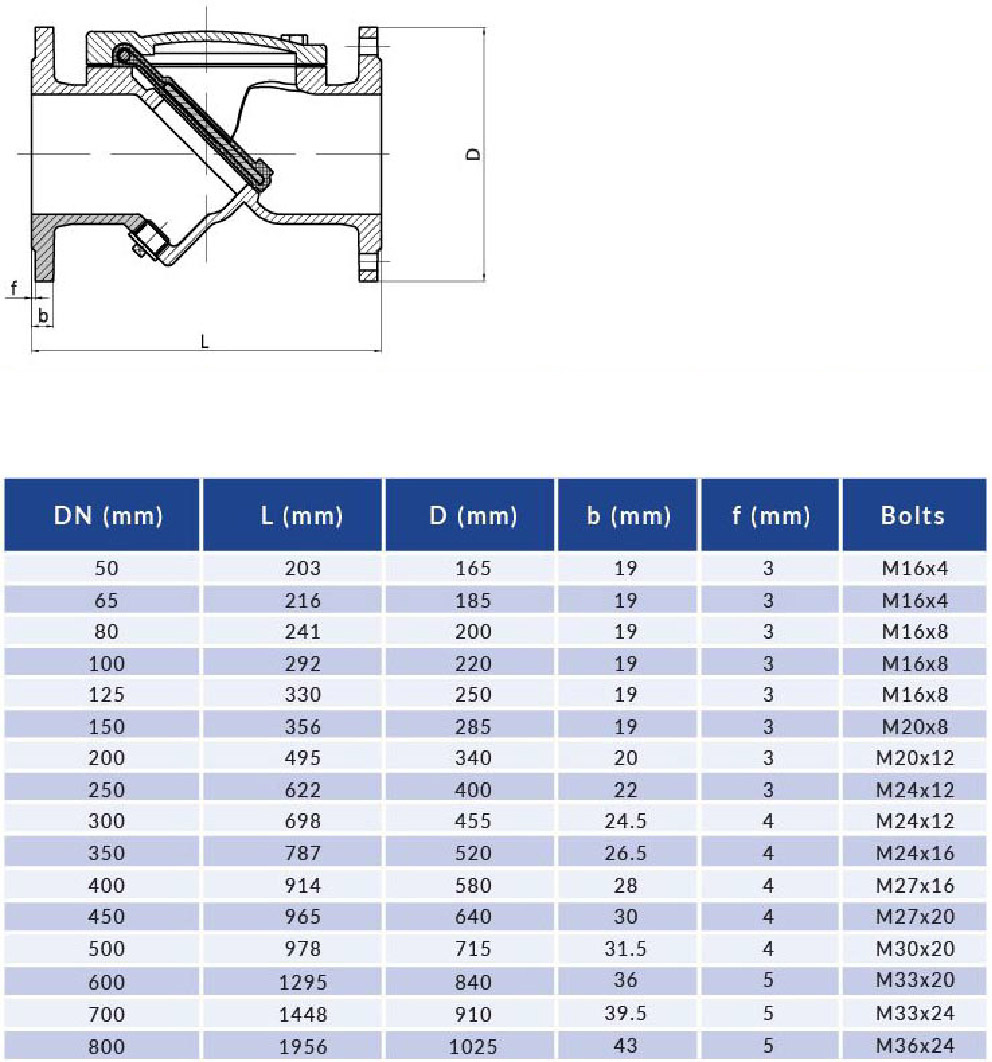

• For water hammer prevention in water and sewage applications. • Working Pressure : 10/16 bar • Shell Pressure : 15/24 bar • Seat Pressure : 11/17.6 bar • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : BS EN 12334 / BS EN 16767 • Test : BS EN 12266 • Flange : BS EN 1092-2 • Face to Face : BS EN 558-1 . Features • Range of Valve Sizes : DN50 to DN800 • One Moving Part Of Disc With Less Maintenance • Full Size Top Access Port Area With Domed Shaped Cover, Allowing

• Easy Disc Replacement.• Designed For A Wider Body Area With Minimum Open Disc &

• Seat Equal To Full Port Area Of The Pipe Size• A Threaded Port With Plug At The Bottom Of The Valve To

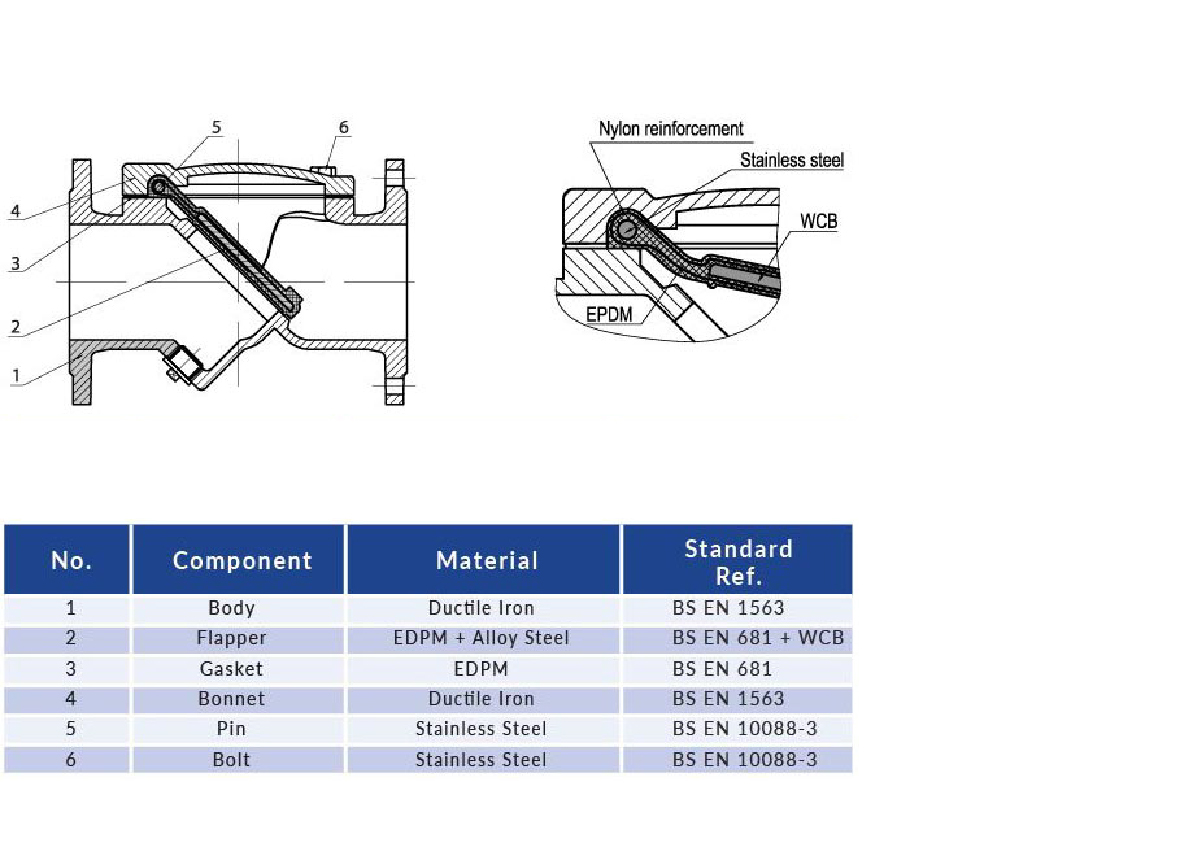

• Allow Backflow Actuator Installation. - 2Parts List & Materials

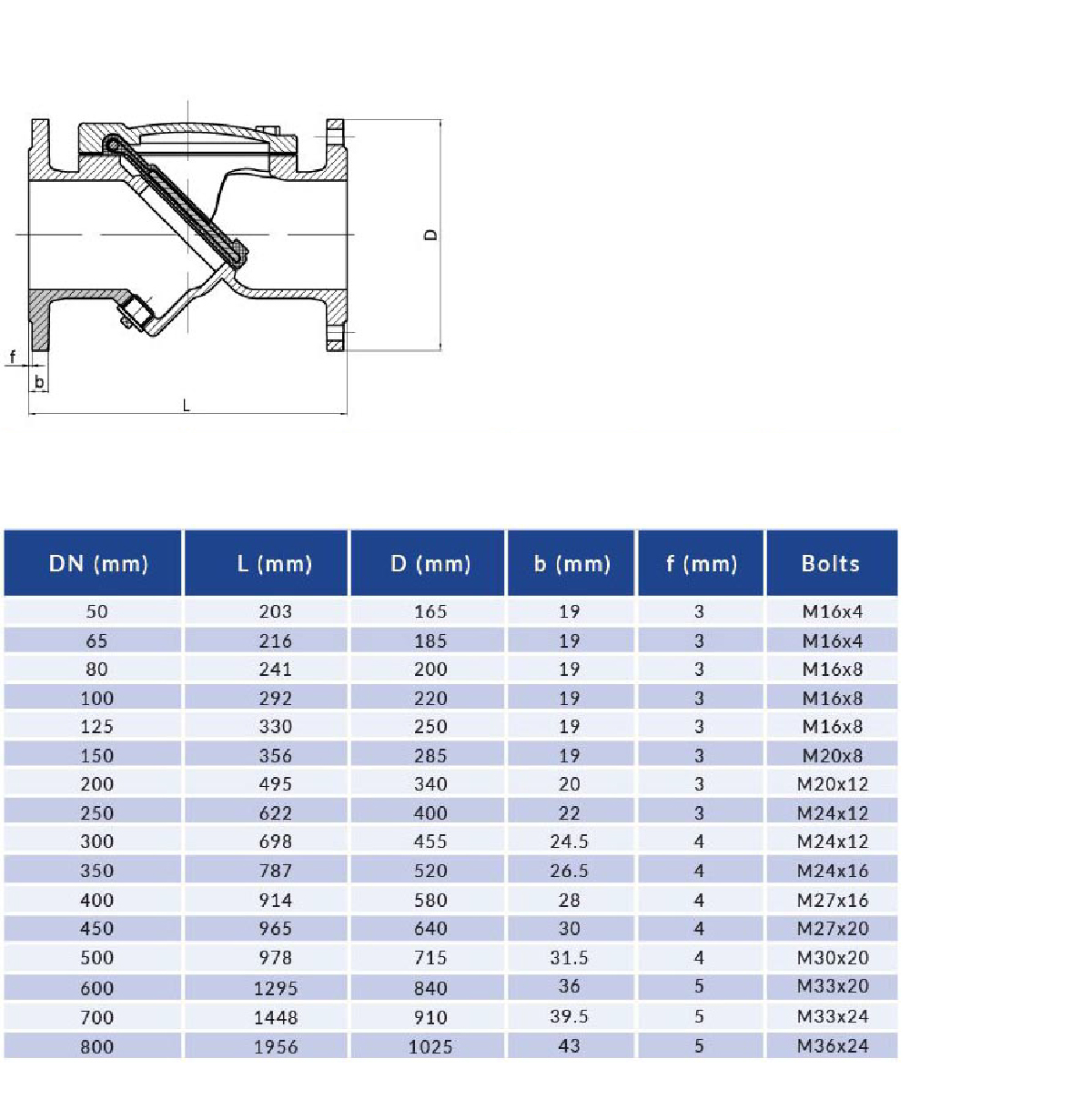

- 3Specifications & Parameters Chart

CHECK VALVES

RUBBER FLAP TYPE

Non-Slam Type Swing Check Valve

- 1Description

LYE Ductile Iron Rubber Flap Type Check Valve, also known as non-return swing check valves, are the most common type of check valves used. Non-slam type check valve is of a streamline design with only one moving part, the flexible disc, and body seat at a 45° angle to minimize disc travel. The disc is of one-piece construction, precision moulded with an integral o-ring type sealing surface, and contain alloy steel and nylon reinforcement in the flexible hinge area. The flex portion of the disc shall be warranted for 25 years against tear-off. Non-slam closing characteristics is provided through a short 35° disc stroke suitable for dynamic of the pumping system.

• For water hammer prevention in water and sewage applications. • Working Pressure : 10/16 bar • Shell Pressure : 15/24 bar • Seat Pressure : 11/17.6 bar • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Design : BS EN 12334 / BS EN 16767 • Test : BS EN 12266 • Flange : BS EN 1092-2 • Face to Face : BS EN 558-1 . Features • Range of Valve Sizes : DN50 to DN800 • One Moving Part Of Disc With Less Maintenance • Full Size Top Access Port Area With Domed Shaped Cover, Allowing

• Easy Disc Replacement.• Designed For A Wider Body Area With Minimum Open Disc &

• Seat Equal To Full Port Area Of The Pipe Size• A Threaded Port With Plug At The Bottom Of The Valve To

• Allow Backflow Actuator Installation. - 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1