REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1

JOINT RESTRAINT SOLUTIONS

UNI-FLANGE ADAPTOR FOR DI & MS

Restraint Flanged System for Connecting Spigot End

- 1Description

LYE Ductile Iron Uni-Flange Adaptor is ideal on Ductile Iron, DI & Mild Steel (MS), British Standard pipes, and other pipe materials with similar outside diameters where retro-fittings at job site is required. Pipe flanging can be easily fabricated on site using plain end pipe without the need of any special tools and the flange restraint is provided by means of a set screw locking device. Alternate Solution to threaded and welded flanges for all project-site conditions allowing flexible and easy installation advantages & future maintenance capabilities on all flanged equipments. . • Ideal for Quick & Emergency Pipeline Installation, Repairs, Maintenance

• & Services Works For Connecting Flanged Equipments With Spigot or

• Plain-Ended Pipe/Fittings• Great Installation Advantages With Built-in End Restraint System

• Allowing Minor Pipe Deflection & Emilinating Bolt Hole alignment

• Problems• Working Pressure : PN10/PN 16 • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Test : EN 12266-1 • Flange : EN 1092-2 • For Ductile Iron Pipe : BS EN 545 / ISO 2531 / MS 1919 • For Mild Steel Pipe (DN100 – DN300) : BS 534 / SPAN TS 21827 /AS 1279 . Features • Range of UNI-Flange Sizes : DN80 – DN400 • Unique flange system designs to keep project moving and water

• downtime savings.• Ideal solution to pre-fabrication for all project-site conditions

• with system flexibility• Alternate Solution to threaded and welded flanges For Connecting

• Spigot End• Additional Thrust Restraint ( Tie Rods ) To Be Special Consideration

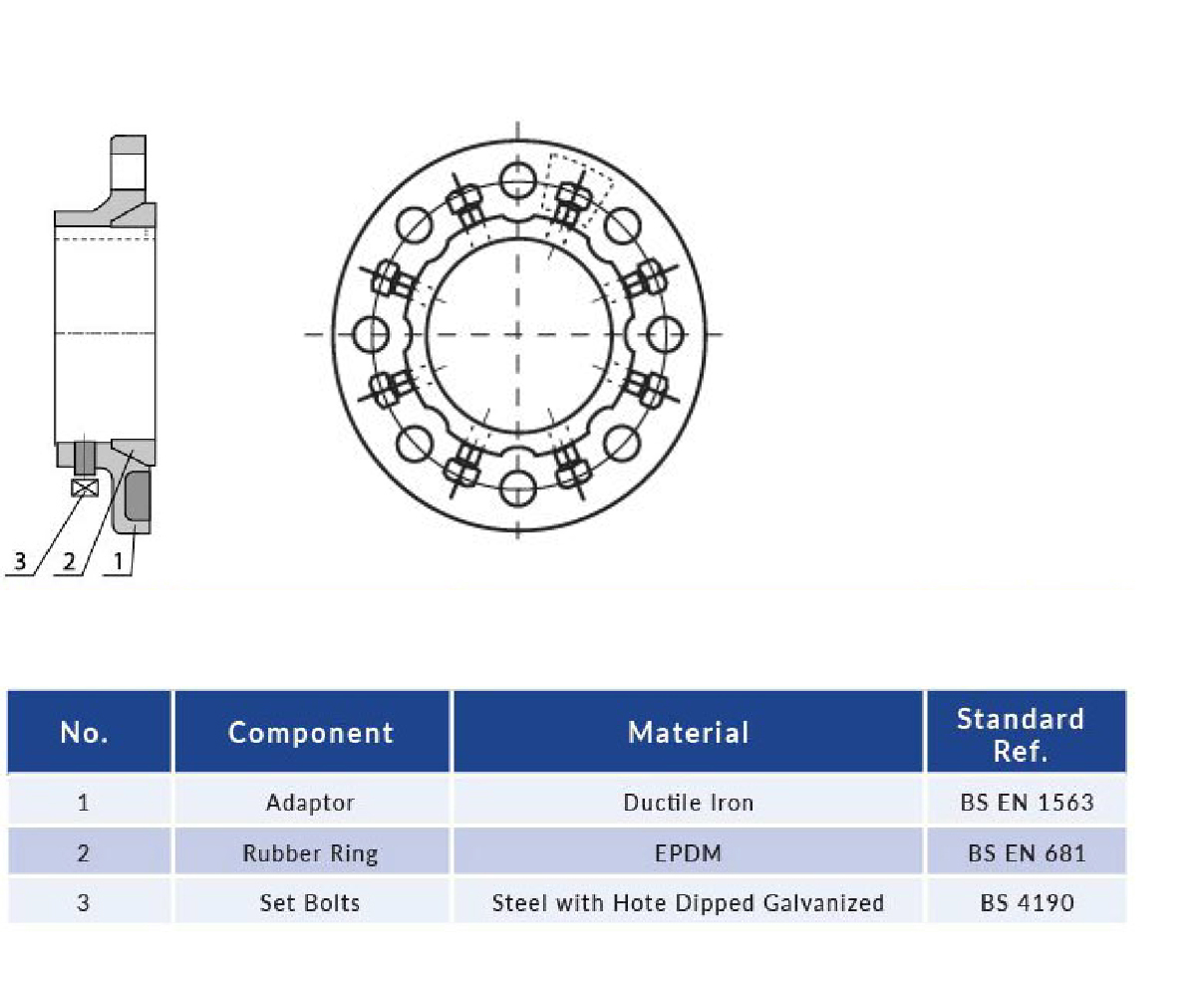

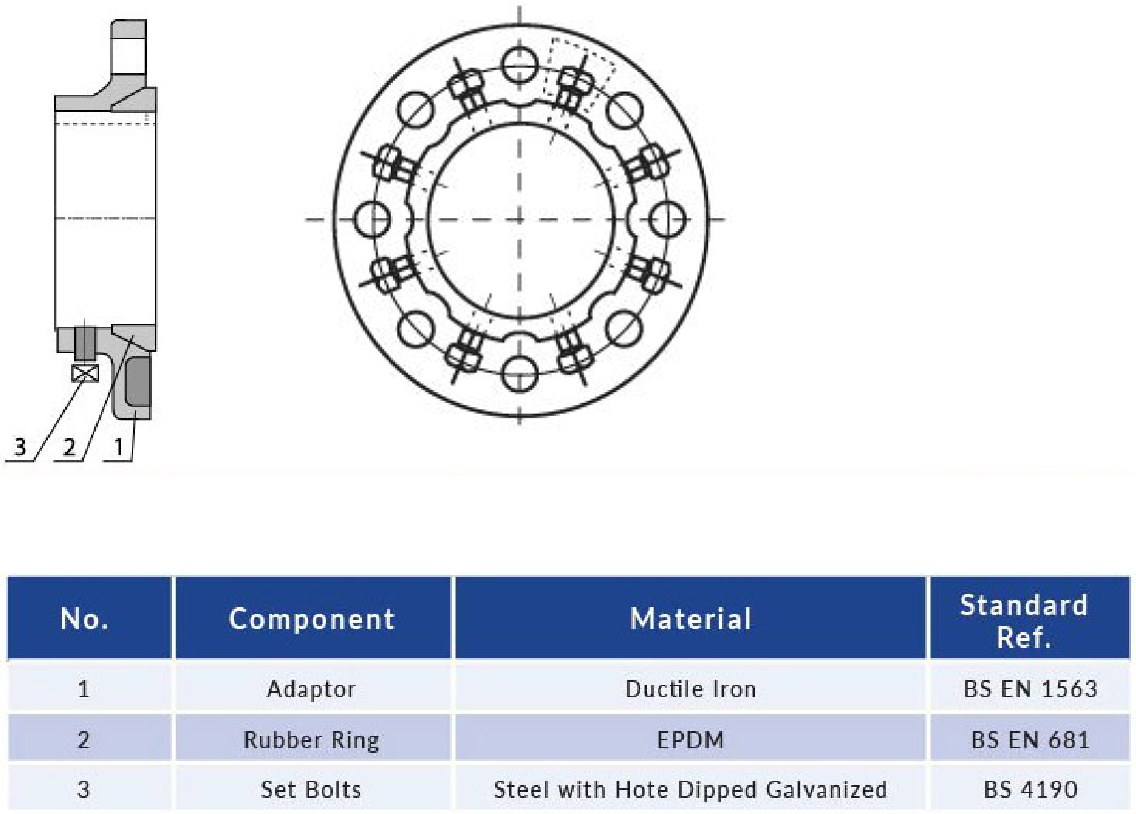

• In Installations Where Rapid Or Excessive Surges & Thrust is encountered - 2Parts List & Materials

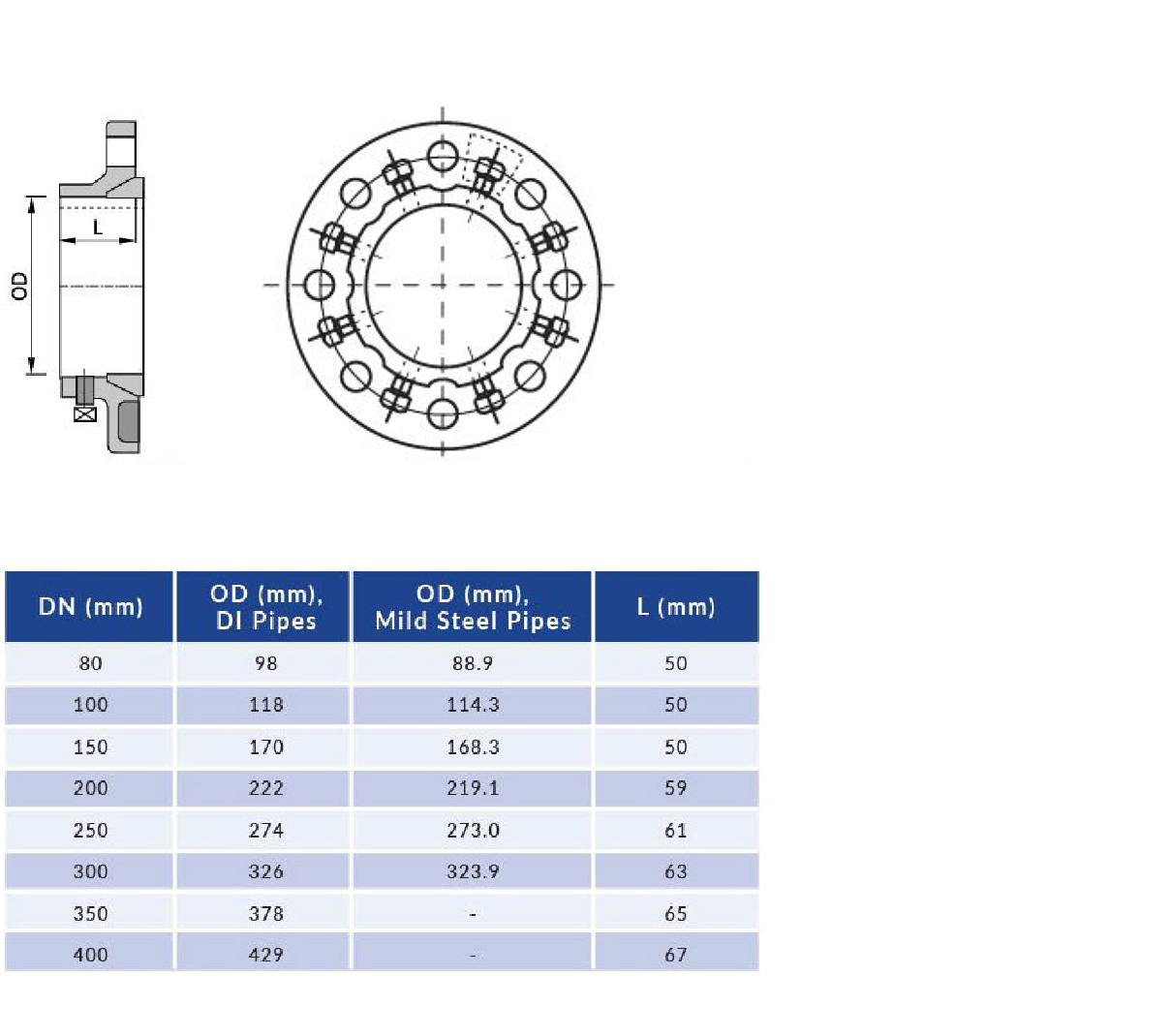

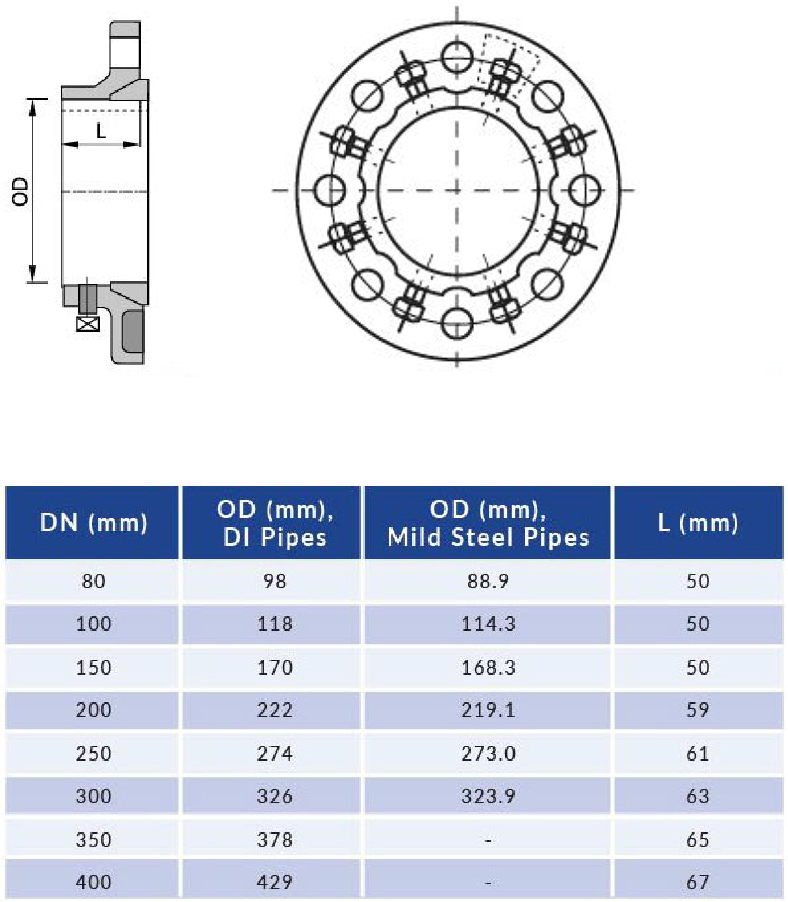

- 3Specifications & Parameters Chart

- 4Video

JOINT RESTRAINT SOLUTIONS

UNI-FLANGE ADAPTOR FOR DI & MS

Restraint Flanged System for Connecting Spigot End

- 1Description

LYE Ductile Iron Uni-Flange Adaptor is ideal on Ductile Iron, DI & Mild Steel (MS), British Standard pipes, and other pipe materials with similar outside diameters where retro-fittings at job site is required. Pipe flanging can be easily fabricated on site using plain end pipe without the need of any special tools and the flange restraint is provided by means of a set screw locking device. Alternate Solution to threaded and welded flanges for all project-site conditions allowing flexible and easy installation advantages & future maintenance capabilities on all flanged equipments. . • Ideal for Quick & Emergency Pipeline Installation, Repairs, Maintenance

• & Services Works For Connecting Flanged Equipments With Spigot or

• Plain-Ended Pipe/Fittings• Great Installation Advantages With Built-in End Restraint System

• Allowing Minor Pipe Deflection & Emilinating Bolt Hole alignment

• Problems• Working Pressure : PN10/PN 16 • Coating : Fusion Bonded Epoxy • Sealing : EPDM . Standards • Test : EN 12266-1 • Flange : EN 1092-2 • For Ductile Iron Pipe : BS EN 545 / ISO 2531 / MS 1919 • For Mild Steel Pipe (DN100 – DN300) : BS 534 / SPAN TS 21827 /AS 1279 . Features • Range of UNI-Flange Sizes : DN80 – DN400 • Unique flange system designs to keep project moving and water

• downtime savings.• Ideal solution to pre-fabrication for all project-site conditions

• with system flexibility• Alternate Solution to threaded and welded flanges For Connecting

• Spigot End• Additional Thrust Restraint ( Tie Rods ) To Be Special Consideration

• In Installations Where Rapid Or Excessive Surges & Thrust is encountered - 2Parts List & Materials

- 3Specifications & Parameters Chart

- 4Video

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1