REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1

JOINT RESTRAINT SOLUTIONS

PUSH-ON JOINT RESTRAINT HARNESS FOR DI

For Restraining of DI Socket Push-On Joints

- 1Description

LYE Ductile Iron Push-On Joint Restraint Harness for restraining of ductile iron socket push-on joints of ductile iron pipelines complying to BS EN 545, ISO 2531 & MS 1919. LYE Push-On Joint Restraint Harness is designed for providing significant restraint against longitudinal sepration other than the friction between the gasket and the plain-ended of the pipe & fittings with adding security by friction clamps with tie-rods. Ideal for underground and aboveground pipeline installation, in any system applications result in unbalanced forces of hydrostatic or hydrodynamic causing joint separation.

• For Restraining Of Ductile Iron Socket Push-on Joints Against

• Longitudinal Socket Joint Seperation• Working Pressure : PN10/PN 16 • Coating : Fusion Bonded Epoxy . Standards • Test : EN 12266-1 • For Ductile Iron Pipe : BS EN 545 / ISO 2531 / MS 1919 . Features • Range of Push-On Joint

• Restraint Harness Sizes: DN80 – DN300 • Ideal for underground and aboveground pipeline installation, in

• any system applications ( By pass Pipeline, Difference in Height,

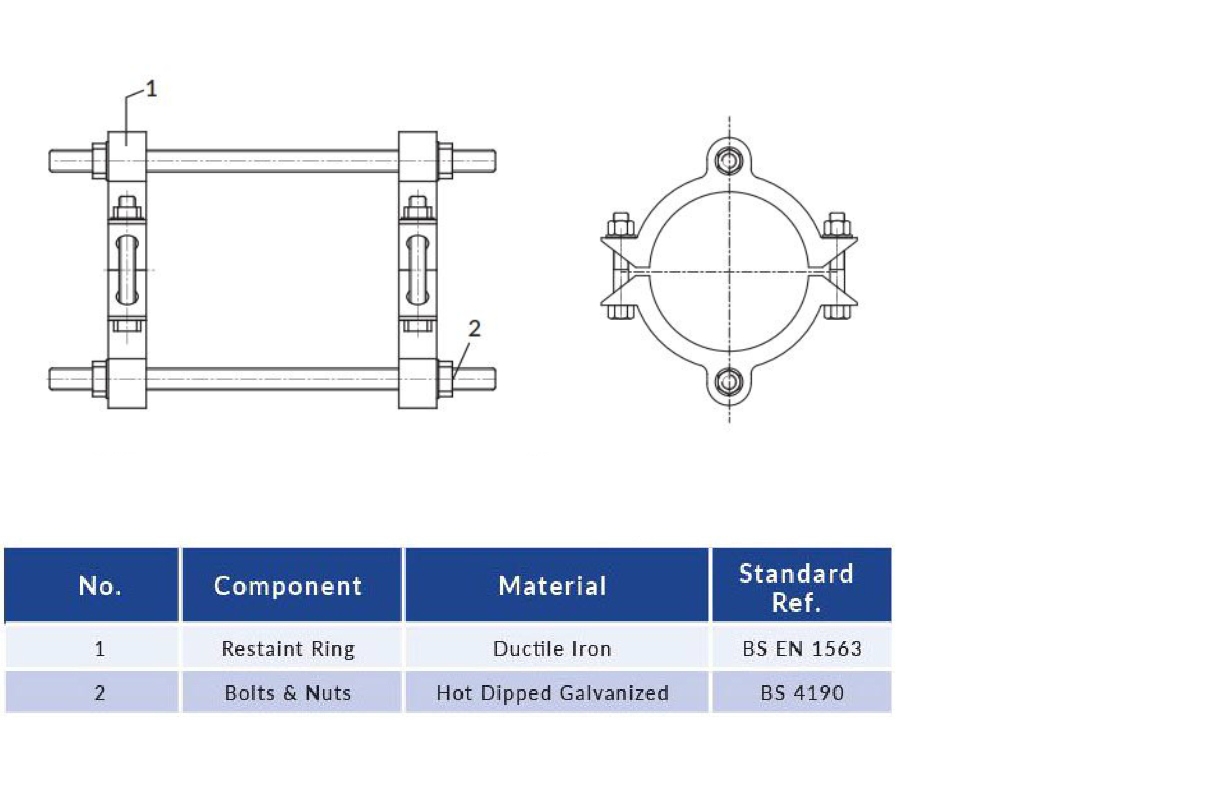

• Internal Forces Raised By Pressure & Bridge Crossing) - 2Parts List & Materials

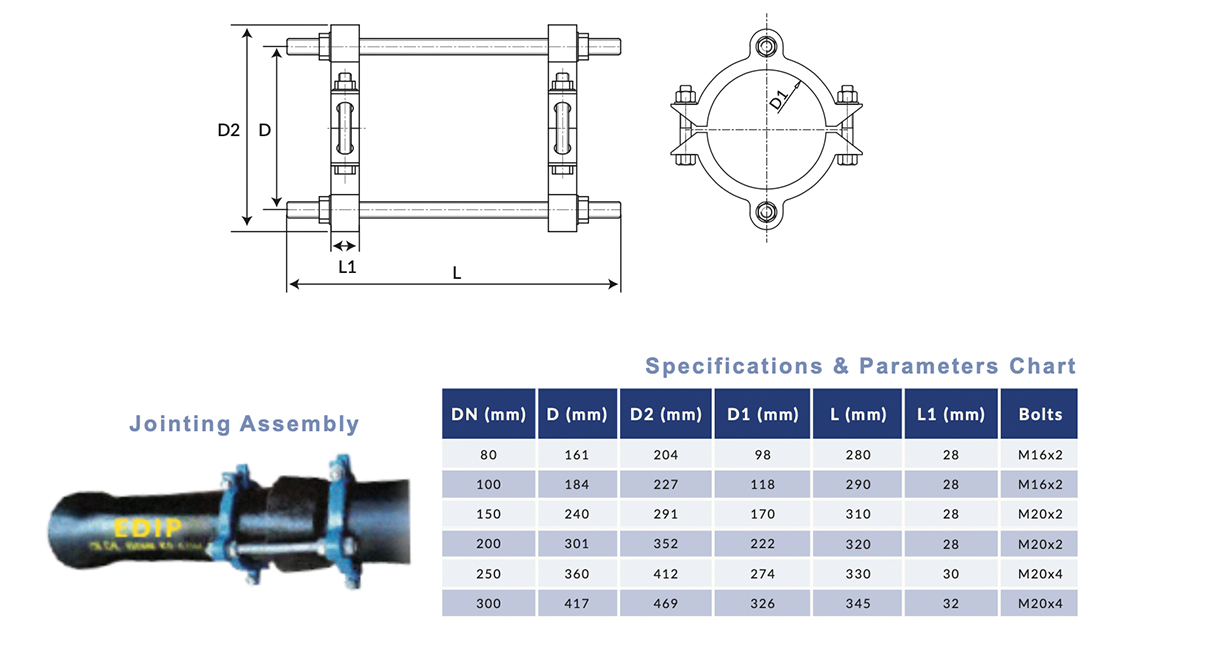

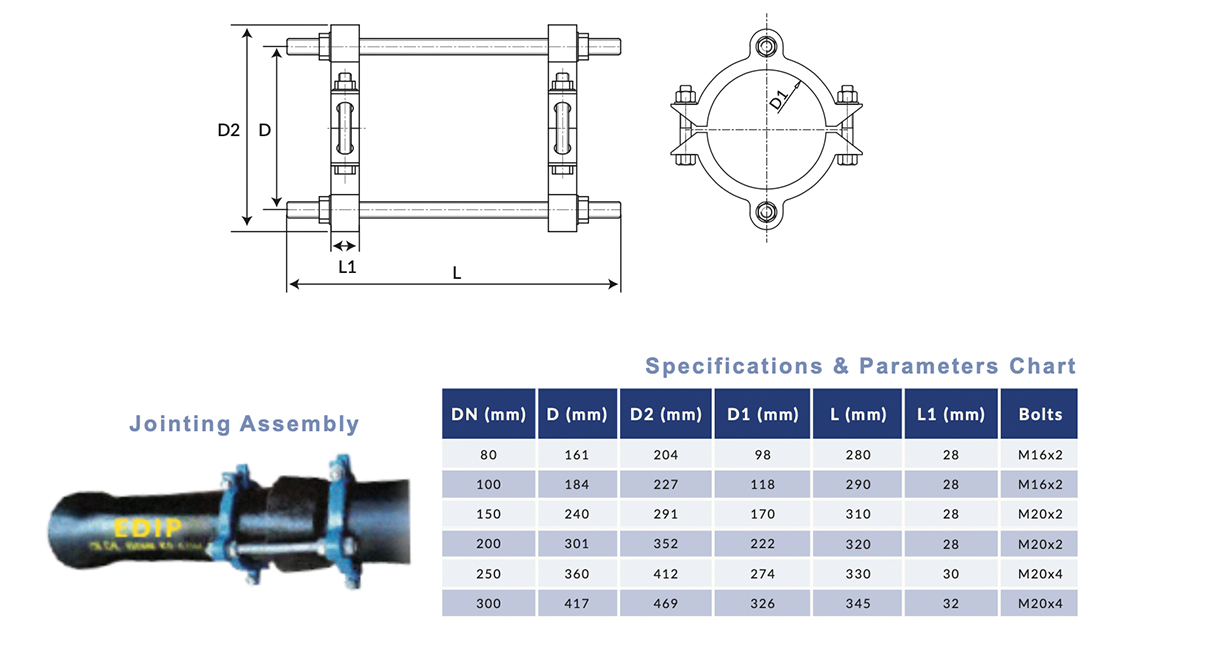

- 3Specifications & Parameters Chart

JOINT RESTRAINT SOLUTIONS

PUSH-ON JOINT RESTRAINT HARNESS FOR DI

For Restraining of DI Socket Push-On Joints

- 1Description

LYE Ductile Iron Push-On Joint Restraint Harness for restraining of ductile iron socket push-on joints of ductile iron pipelines complying to BS EN 545, ISO 2531 & MS 1919. LYE Push-On Joint Restraint Harness is designed for providing significant restraint against longitudinal sepration other than the friction between the gasket and the plain-ended of the pipe & fittings with adding security by friction clamps with tie-rods. Ideal for underground and aboveground pipeline installation, in any system applications result in unbalanced forces of hydrostatic or hydrodynamic causing joint separation.

• For Restraining Of Ductile Iron Socket Push-on Joints Against

• Longitudinal Socket Joint Seperation• Working Pressure : PN10/PN 16 • Coating : Fusion Bonded Epoxy . Standards • Test : EN 12266-1 • For Ductile Iron Pipe : BS EN 545 / ISO 2531 / MS 1919 . Features • Range of Push-On Joint

• Restraint Harness Sizes: DN80 – DN300 • Ideal for underground and aboveground pipeline installation, in

• any system applications ( By pass Pipeline, Difference in Height,

• Internal Forces Raised By Pressure & Bridge Crossing) - 2Parts List & Materials

- 3Specifications & Parameters Chart

REQUEST FOR CONSULTATION

Please don’t hesitate to complete the form below. Our office will respond to your interest shortly and we are looking forward to work with you.

1

Step 1